There are many ways to do just about everything and sanding tube is no different.

Finishing and sanding tube or pipe

Finishing tubes can be easy.

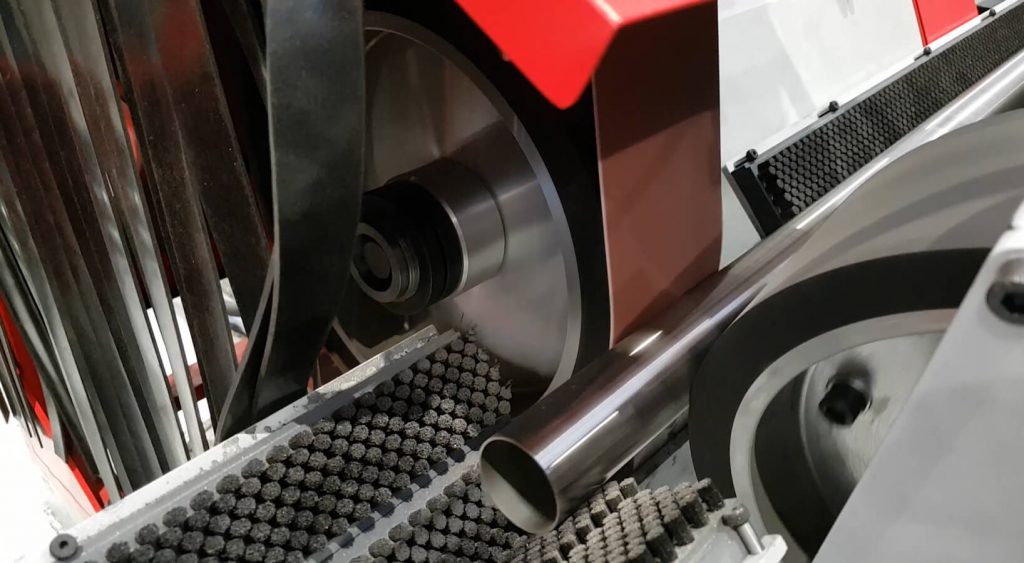

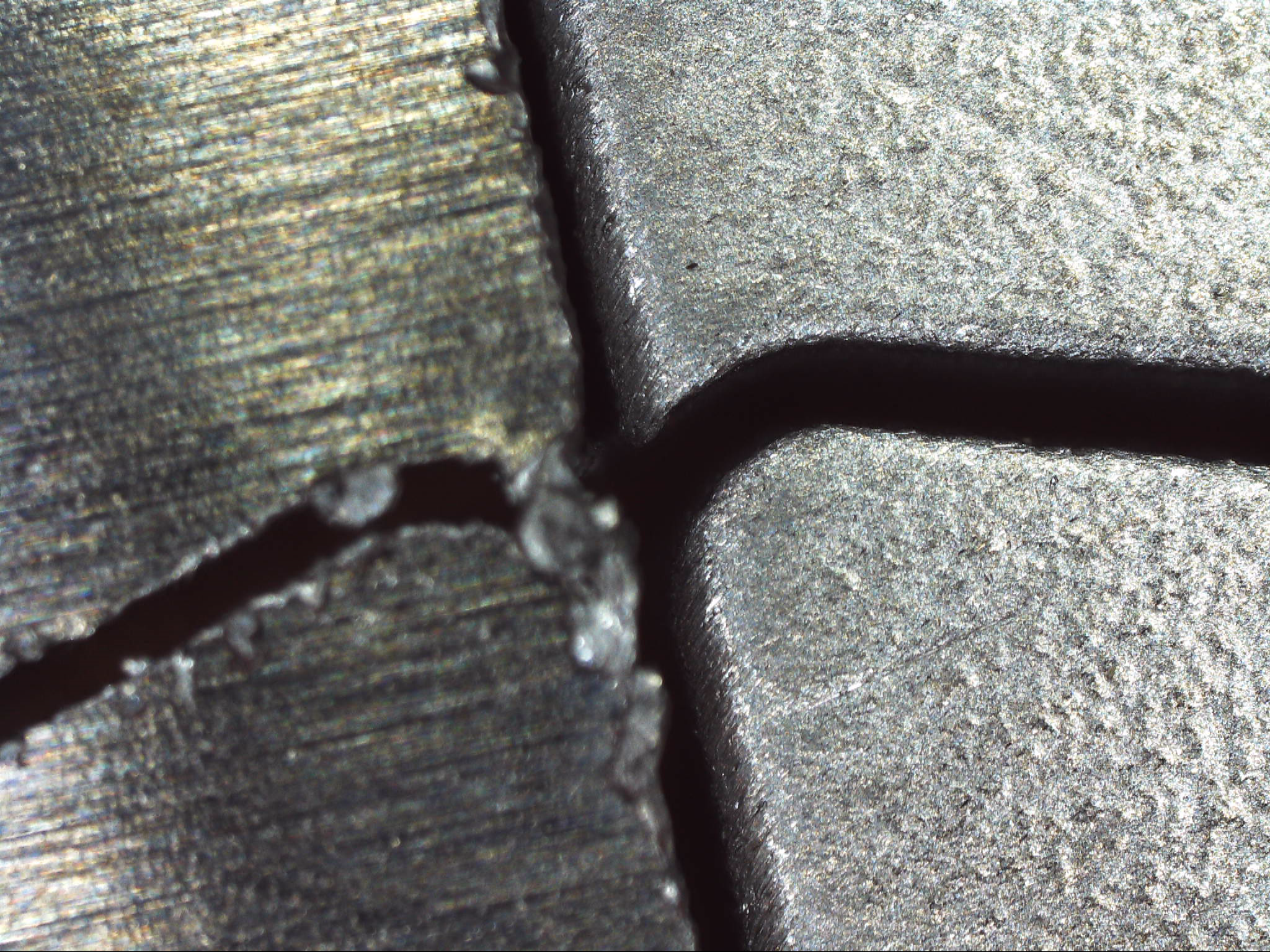

One of the tasks that tends to be problematic is the OD finishing of tube material. From hand finishing to placing tubes in a lathe there are all manner of ways people try to work with tubes. In reality there is a much more simple and fast way to do it that it seems many are not aware of. There is the centerless style of machine most have seen where the tube spins while being processed. Many are not fans of these due to the risks of the spinning tube. If there is a bend to the material the tube can flail around and get out of control. They also tend to be aggressive in a general sense as far as material removal. If you have nasty rust covered material with severe pits they would be the best option.

Labor intensive tasks

Dealing with tasks that require a lot of labor or hand work is a way to improve processes and trim costs. This is not to say eliminate jobs but rather put the staff to tasks that better use their skill. Helping to make the people more efficient by providing better tools is a way to do this. From finishing enclosures to mirror polishing the finishing tasks tend to be the most manual.

Rather than have four people doing bur removal by hand a through feed machine can speed this way up and provide more consistent parts. Don't size the machine based on you starting material size but rather the part size you cut from that material. Getting a machine sized to your starting material tends to be a good way to spend more than you need to. Machines like the Loewer also let you do the small parts that tend to be done by hand safely.

In a situation where there is a small army hand finishing enclosures bring a stroke sander online. With a good twin belt unit you can cut handling and greatly increase speed. If you opt for one that has a 3D part mount it increases the speed and ease of use further. One belt will cut the welds and the other blends the finish all with out a belt change or moving the part. Quality and speed are both increased while maximizing labor. KBM machines come setup to fill this task by default.

Polishing tends to be a massive labor sponge. Real polishing where you are going for a #8 mirror takes several steps with several abrasives. It is also dirty and physically draining. The best polisher cant keep the same quality level all day as they get tired. That causes a variation in finish just across their parts each day. Now compound that by 6 or more people polishing and consistency becomes a pipe dream. Custom polishing systems tend to have a high buy in but make massive improvements once running. From worker safety and morale to part consistency every aspect tends to see sizable improvements. Getting a higher volume of parts with a much more consistent finish is just the start. Anything from high volume CNC to fine detail robotics are possible with Autopulit and they are built around your needs and not a one size fits all.

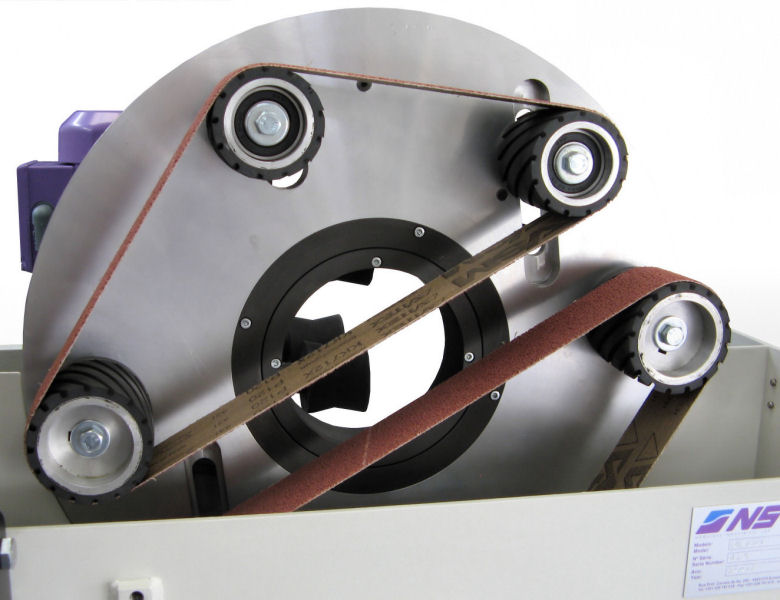

Tube finishing is another area many struggle with. As with other material the same issue exist here. Your standard chuck it in a lathe is just so slow and ties up an other wise useful machine with a task it was not designed to do. There are small machines that can put any finish you need on tube and safely. Machines that spin the tube should be avoided if possible due to safety issues. As even a slight bend can cause things to go from zero to crazy in a blink and no one wants to see someone injured. A small simple planetary style tube sander can process 3 feet or more per min and automatically feed the material through the machine. Its a simple yet genius machine that can drastically speed up the process with fewer people all while being safer. Here is where the ML machines from NS can resolve the tube sanding issues quickly and safely.

Looking at the finishing side is an easy way to trim production costs while using fewer people and getting better parts overall. With the reduced quality of raw material most are having to use this becomes more of a key point. What was labor intensive with good materials has now gotten much worse. We can help with these issues and more and advice is always free. If you have a specific issue talk with us and take advantage of the years of experience we have is improving finishing processes.

Centerless Grinding Basics for Tube Finishing

This is the second in a four-part series of blog posts about tube finishing. Click here to read part one.

In centerless grinding, a cylindrical part is supported by a work rest blade and rotated by a regulating, or feed, head.