One of the many labor intensive and problematic operations is dealing with welds. I want to talk a bit about what you can do to remove much of the stress from these operations. I cant cover every single aspect or give every detail here but I want to touch on some of the larger points.

One of the first things that tends to be looked at is automating the welding operation. In many cases this can be to increase volumes. Having automated welding allows the more predictable flow of material as the programmed operation works in a set time. With that you can calculate the total part count that can be produced with reasonable accuracy. With hand welding this calculation is much harder. It can also be automated for more consistent welds. Again the programed operation should be the same every time providing a predictable end result. With hand welding this is near impossible even with good fixtures and very skilled welders. In some cases it is automated due to labor issues. Skilled welders are not as easy to find these days and it creates all manner of issues in manufacturing. Automating the welding can often side step the issue.

So you spend the time and effort to automate the welding operations for any number of reasons. Now what? You still need to grind down the weld or blend the finish and remove any discoloration. Now it shifts back to a manual operation where a lot of the gains are lost. The predictable volumes become an issue as well as the consistency of the final parts. You have taken several steps forward only to get pushed back by manual finishing. Grinding welds is not a job there will be a long line of people looking to do. It can be a role that is tough to staff or keep staffed long term. Its just a dirty job that can be tough physically to do day after day.

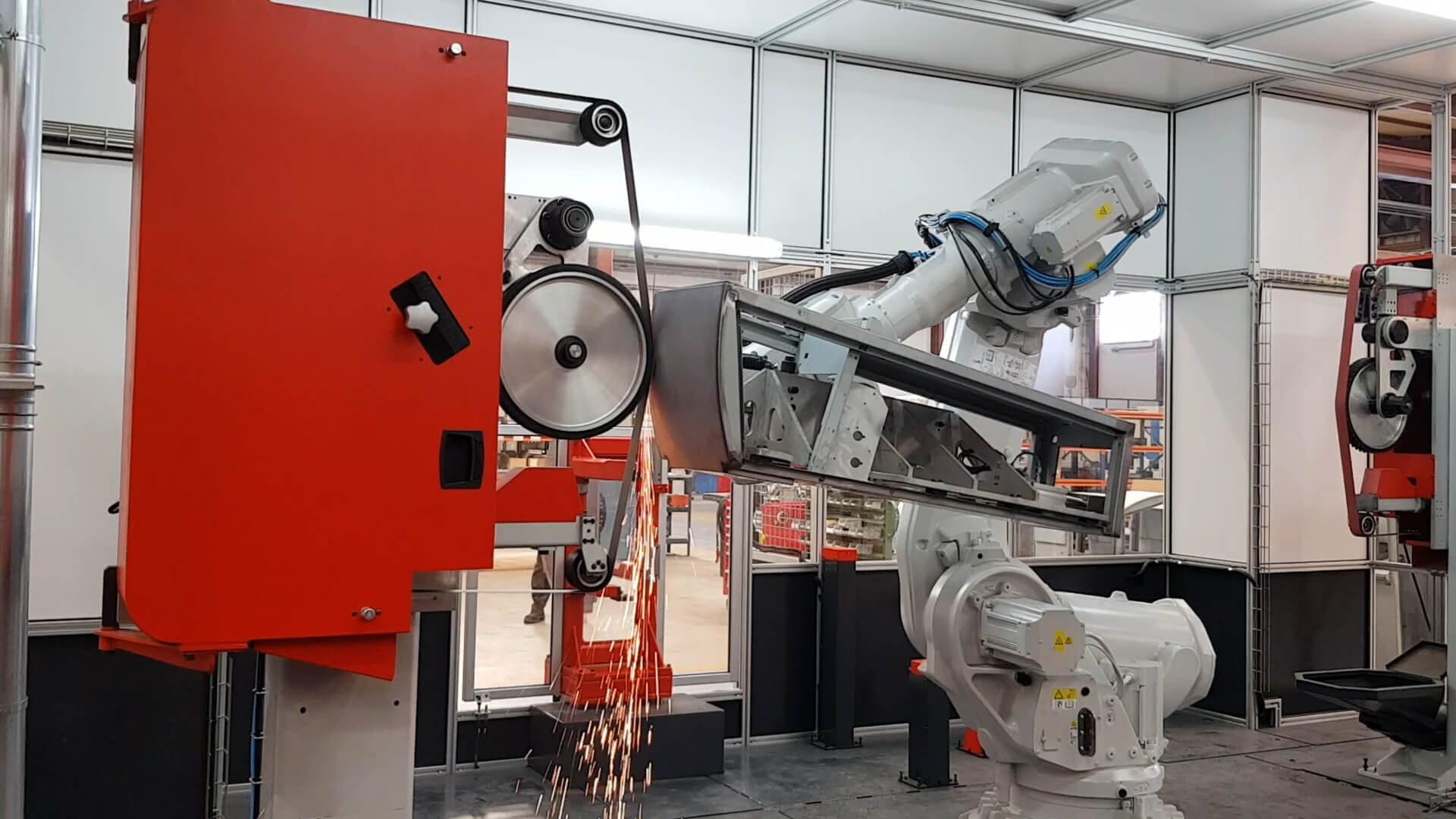

So what can be done to keep the gains from the welding automation? The simple answer is to automate the finishing. Automation thrives on consistency, your consistent automated welds are a prime candidate for automated finishing. You can produce nearly any end result you need with a minimal amount of labor while keeping the speed and consistency you picked up from automating the welding. A few examples are shown in the videos below.

Remove welds on a car door frame?

Remove the welds and blend the finish on medical equipment?

Remove welds on electrical enclosures from huge to small?

Automating the finishing even with manual welding saves time and labor. Why have the skilled welder waste his time grinding when he was hired to weld. Take the finishing operations off his work bench so he can focus on welding more product. You get more product and have happier welders even with manual welding. Another added plus is that when you automate the finishing you get a cleaner shop. With the removal of all the manual sanding the debris is contained and far easier to deal with. An enclosed cell connected to dust collection keeps all the debris out of the air and off the floor.

With more than 50 years in automation we have the experience to solve the finishing challenges you face. We work with you one on one to find out what you need and support you through the entire process from initial design to startup and training of staff. Its easy to get overwhelmed or not know where to even start in dealing with finishing automation. From a very basic operation with finishing tube to mirror polishing a milk tanker, finishing is our passion. We only build the very best and do everything possible to insure you have the very best experience possible. We want to be your go to with any finishing question and work very hard to earn and keep that privilege.

If you have questions on weld finishing or any other finishing operations you want to automate or improve please feel free to reach out. I am always happy to look at processes and offer any advice I can, after so many years in finishing I have seen a lot but not everything and welcome your challenges.

Topics metal finishingpolishingautomotiveweld grindingAutomationRobotics