Everyone looks for ways to have their product stand apart or above their competitors. High end lasers that can churn out complex parts quickly tend to be popular. Lasers are far more common than they once were and not such a stand out currently. The newer lasers do a great job cutting material but there are limits as with everything.

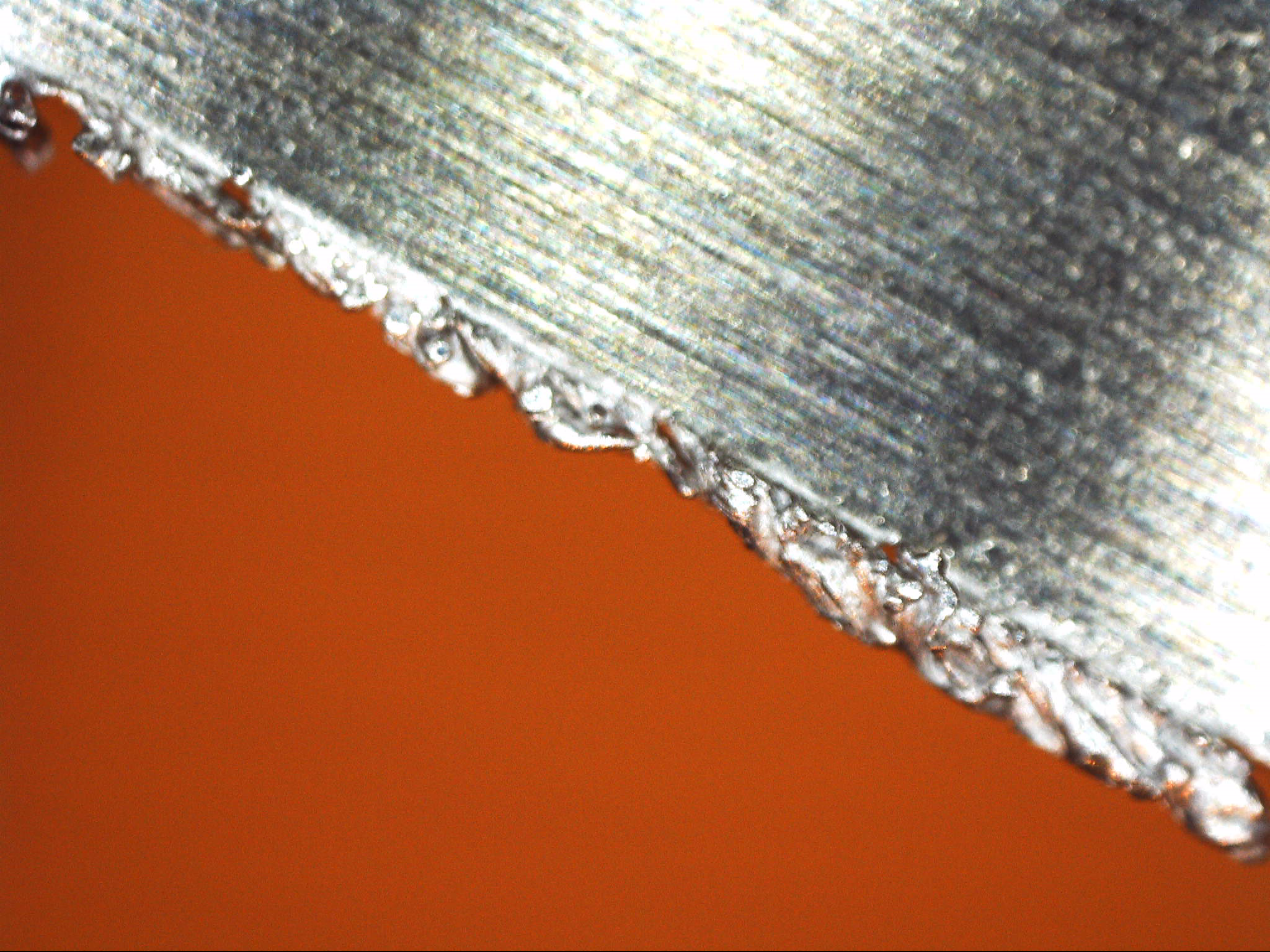

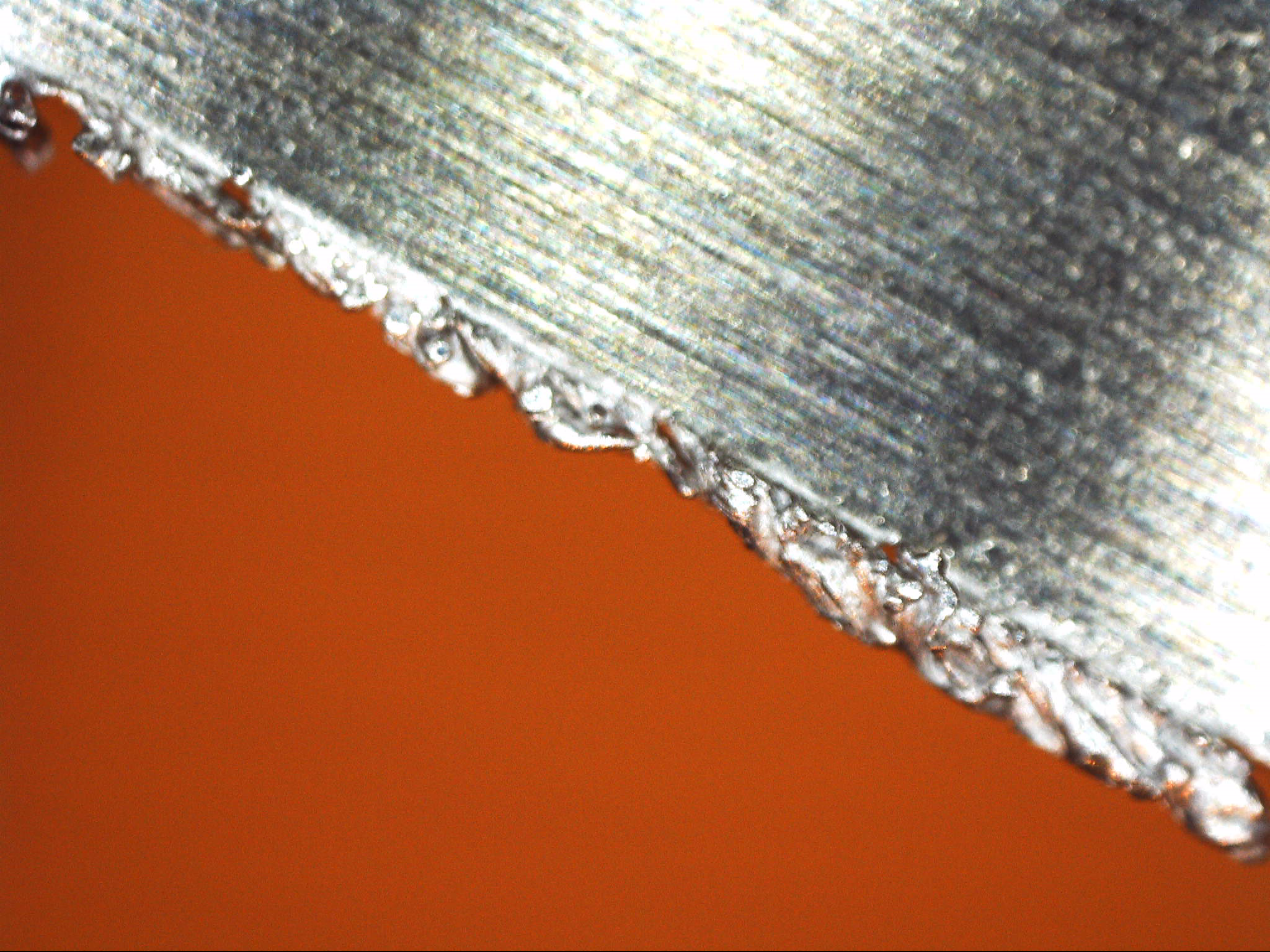

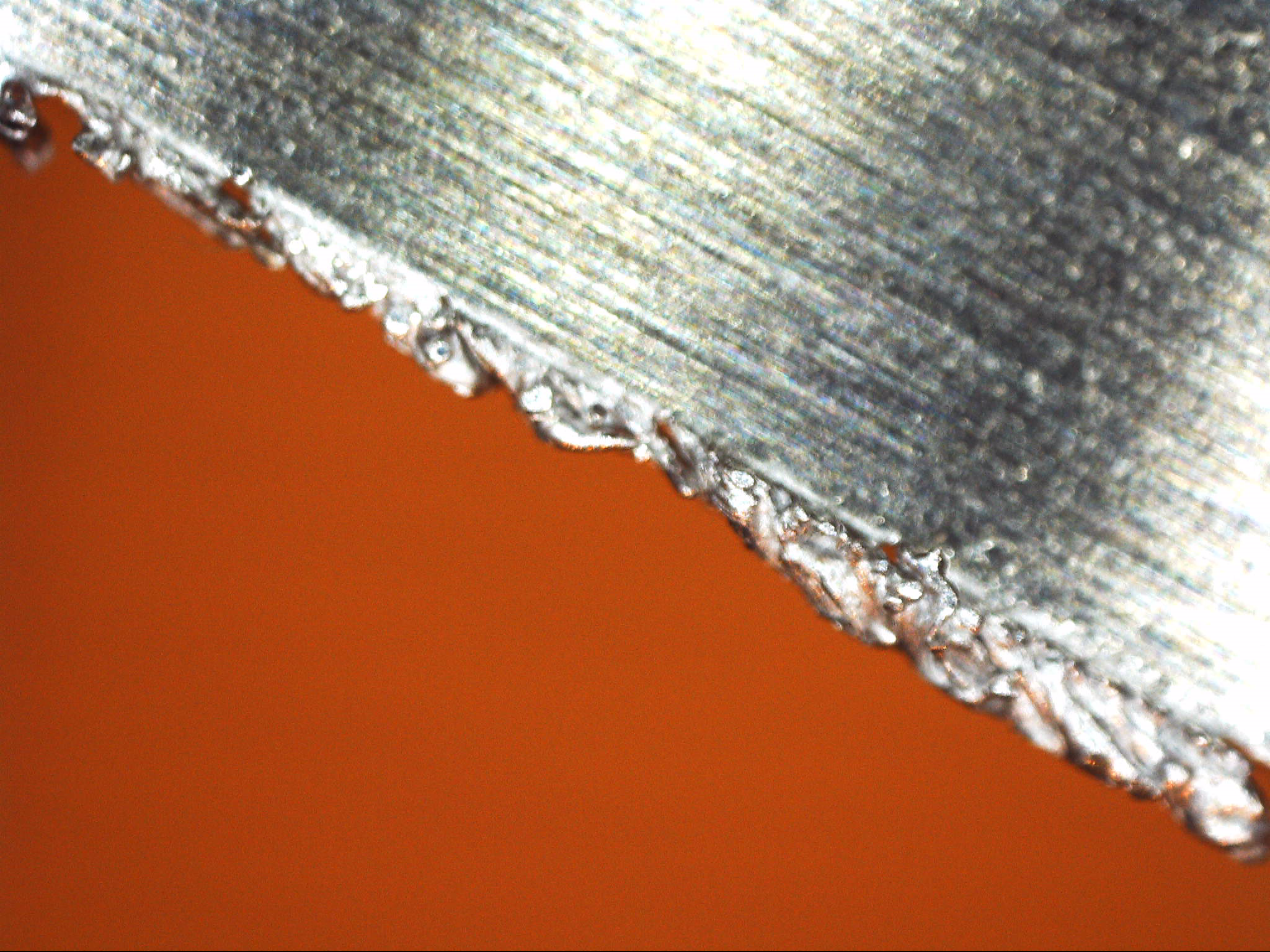

We see a lot of aluminum cut via laser with large saw tooth style burs. When you push the laser speed or thickness wise you start to see this. You could buy a larger laser or slow it down but neither are options most are interested in. The other option would be to finish the parts to remove the large bur.

If you are in a situation where you are pushing your laser then you have more volume than you want to hand finish. Getting a machine to do that task makes sense vs spending a fortune on a larger or additional laser. You can keep the lower power laser viable longer by cleaning up its cuts. This could buy you several years of service on that laser by spending far less than the cost of a laser, not to mention that parts from your punch or shear can be processed as well.

The new lasers are billed as bur free but that just seems to not be the case. Even cutting with quality gas it seems there is still a bur. Having that final step that gives all of your parts some uniformity helps to make things predictable. You know what your edges will look like and know what your surface finish will be. Keeping these things predictable cuts down on variables and can reduce material in the scrap bin.

Better coating adhesion and removing the risk of cuts from sharp edges is the just the start. Being able to deal with bad runs on the laser and avoiding scrapping all the parts adds up. Having parts that are safer to handle could be just the thing to make your process and parts stand out over the competition. Offering the added service to existing customers could work to help with customer retention and new work from them. These are just a few of the points tend to come up often. Please contact us if you need advice or help with your finishing process.