One of the more common tasks I am asked about day to day is dealing with round tube. There is so much of it used in all manner of products its seems near every one has to deal with it in some way or to some extent. It can be a simple process or as complex as putting together that build it yourself furniture we all love.

Out side of manual tasks I will cover the two main ways to do tube finishing with a machine for the task. As there are two main ways so this should not take too long.

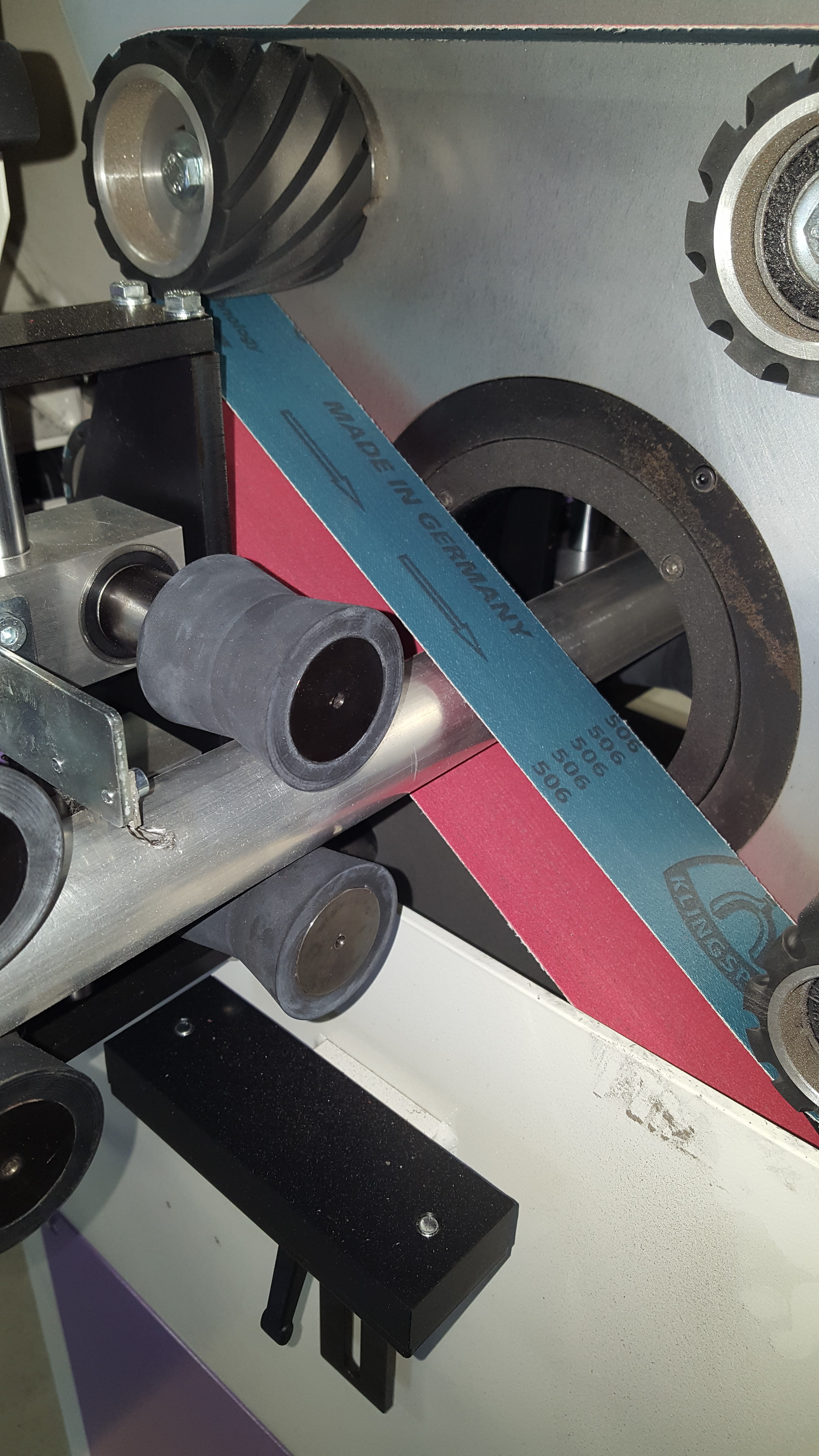

First you have a centerless style of machine.

In a centerless you have a rubber coated drive roller that spins the tube while driving it through the machine. In the image above you can see the drive roller on the right side of the tube. The drive roller serves several tasks one of them is holding the material in line for the sanding belt. You can have one station like this or many depending on what you need.

Some positives of this style:

- Speed

- Aggressiveness

- Ability to fit polishing buffs

Some negatives:

- No way to work with bent material

- The fact the tube spins can be dangerous

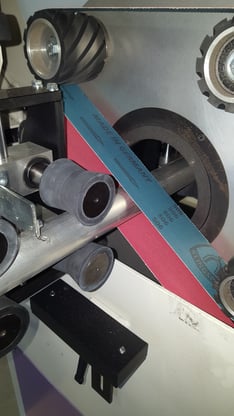

The second way to process round material is with a planetary style machine.

With a planetary style machine the largest difference is that the tube will not spin. The belts turn around the material while it is fed through the machine. In these machines the feeding system is separate from the processing so you do not have parts filling more than one task. These can also be had with one station or many depending on what is needed.

With a planetary style machine the largest difference is that the tube will not spin. The belts turn around the material while it is fed through the machine. In these machines the feeding system is separate from the processing so you do not have parts filling more than one task. These can also be had with one station or many depending on what is needed.

Some positives:

- Tube will not spin

- Can do bent material

- Smaller foot print

- More simple design

Some negatives:

- Less aggressive

- Can be slower vs centerless

- Can not be fitted with buffs

So what is better? well it depends on what you need to do more than anything else. If you just need to sand long lengths of material quickly the centerless might be best. You have to be careful if the tube has any bend or bow to it as it can flail around if not controlled. If you need to finish bent material or do not want to remove a ton of material then planetary would probably be best. In a very general sense either style can do the job with a few exceptions. If you need to do bent material for example you have to use a planetary. Either machine can make just about any finish you need as it is 100% dependent on the abrasives you use. If you put an 80 grit in either machine it will make an 80 grit finish. So there is no finish assigned to either machine and in all likelihood you will need to try different belts to see what works best for you. This aspect is a positive not a negative for either machine. Having the ability to change the belts at will to make a different finish allows for flexibility. Making the finish you need on demand vs getting pre finished material is a cost savings on its own. But storing pre finished and repairing defects from other operations can be an issue. It also lets you have more control on the time side. Holding raw tube in stock and making the finish you need as you need it helps make things more predictable.

That would be the very basics of dealing with tube and I hope it provided a little insight. As is always the case I am happy to answer questions on tube or any other material.

Joe Amick

joe@ammachinerysales.com

Topics tube finishingplanetary grinding machinescenterless or planetary grinding system