There are many ways to do just about everything and sanding tube is no different.

There may be many ways but some are better than others. Some are safer than others and each has pros and cons. Looking at a few of the more common ways can provide a basic understanding of the hows and whys you may need one over another.

A manual process might use a lathe style setup or centers. With the material held on centers you can spin it as needed and then use a hand pad or any hand held tool to make the finish. With short lengths that just need scuffed this might make sense. But what if you need to do a 6 foot length or even a 20 foot length? This method would not be effective for the longer lengths or higher volume. Very low volume and short lengths is where this way would be a reasonable choice.

A centerless style machine is another common way. With centerless you can have a belt or brush working the material while a drive roller spins the material and pushes it through the machine. Centerless tends to be hit or miss, some will swear by it and others wont allow it in their building. Its the spinning of the material that tends to be the point of contention. If you take a 10 foot length of tube and spin it with any speed you will quickly find out if it has any bow or warp to it. It will start to flail around and things will get exciting quickly. While they can be hard to manage and some what dangerous they can remove a lot of material quickly. These style machines are also prone to "barber poling" or a spiral banding effect. It can be tough to diagnose in some cases but adjusting the feed speed to slow it down and give things a good clean are where you should start. The centerless setup also can only do straight material. If you need to remove a lot of material and have dead straight material as well this would be a reasonable choice. But if you have bowed or twisted material be very careful and keep your guard up.

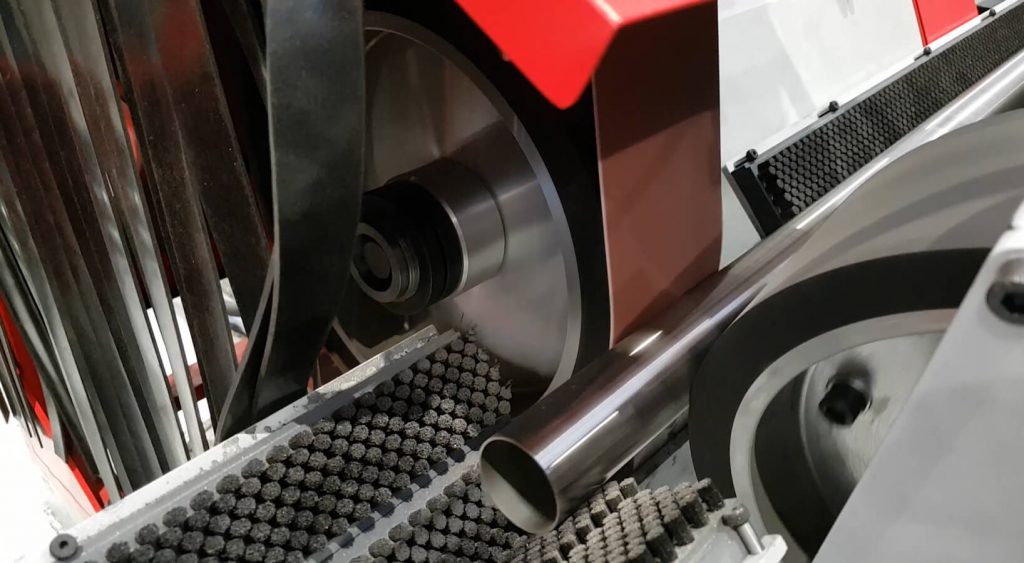

A planetary style machine is another popular option. In a planetary machine the tube is pulled straight through the machine and will not spin. Rather the abrasives spin around the material and is the reason its called planetary. With planetary you avoid the safety issues found in a centerless while still being able to do long lengths if needed. You can also process bent material in a planetary where you can not in a centerless. Planetary machines also are far less likely to have any banding issues in the finish making the finish over all more reliable. The negative to a planetary is bulk removal is not what they are built to do. While you can smooth out a weld seam or remove rust, you will not be able to knock the OD down by a half inch. That would get the material far too hot anyway and smaller OD material should cost a bit less so its not a common need. Planetary machines are great for applying a finish to tube be it bent or straight. This would be a good choice to do finish application and minor defect removal consistently.

Wet vs dry?

No matter what you do a wet tube machine is going to make a mess. You are passing pipe through water and pipe is going to do pipe things like moving that water. No matter how careful you are water will enter the pipe and flow through it and on to the floor. If you need a wet environment like when working Titanium then you do not have much choice and it is what it is. But for other materials dry tends to make less mess and is easier to keep up with. Cutting down the mess and avoiding rust issues tends to be enough reason to pick the dry path here. Get a decent dust collector and go dry unless there is a reason not to.

Take aways,

Manual for very low volume where you do not need to do much to the material.

Centerless if your tube is arrow straight and you need to remove a lot of material.

Planetary if you need to do straight and bent tube or can get bowed material.

Go dry unless there is a compelling reason for wet.

This is just the very most basic points to get a general idea of each. There is far more to making a quality finish consistently and safely. Fell free to contact us to ask questions or find out more any time.

Topics tube finishinghands-off tube finishingcenterless grinderplanetary grinding machinescenterless or planetary grinding systemweld grinding