One of the aspects I am able to see in fair detail is where manufacturing work is being done. While I will admit this more of a rant than anything else it is information none the less.

A company makes a product of some type, this could be welded boxes or even polished wheels. They look to cut production costs and end up sending the work to China. If you think about the added costs of transport, taxation, insurances and many others it would seem to not bring much savings. The reality is that the actual cost per part is low enough to warrant the added costs. How is China able to do it? The old thought was labor is so cheap they can do things not possible any where else.

What I can tell you from a machine builder and automation perspective is this, China will automate with little hesitation. Have you tried to buy a large machine like a press or CNC lately? The long lead times have a lot to do with the demand for machinery in China. China will low bid on a project then figure out how to automate most if not all of it as soon as they get the work. Once one company has the new automation in place it becomes a case of me too. Soon after every company in that area has the same machinery in place. The cycle seems endless and they keep low bidding for any work that comes that way.

There are all kinds of theories as to why the situation in China is the way it is. They range from political issues to long term birth rate and population issues. I am in no way qualified to try and explain this so I will not even try. The general position is that labor in China is around 10% cheaper than the US. The numbers will vary depending on who you ask but it is no where near the 75% of days gone.

So the question,

So why not just automate the work and keep it where it is? That is a question I do not have a clear answer for. There can be many reasons and a complete list would be impossible. What I have seen most often is the fear of living with the automation in what ever form it takes. Having people to program or even just do the day to day upkeep tends to be a topic of worry. In some cases it could be there is fear the contract will change or end. The reasons are all valid to the situation that one may be facing.

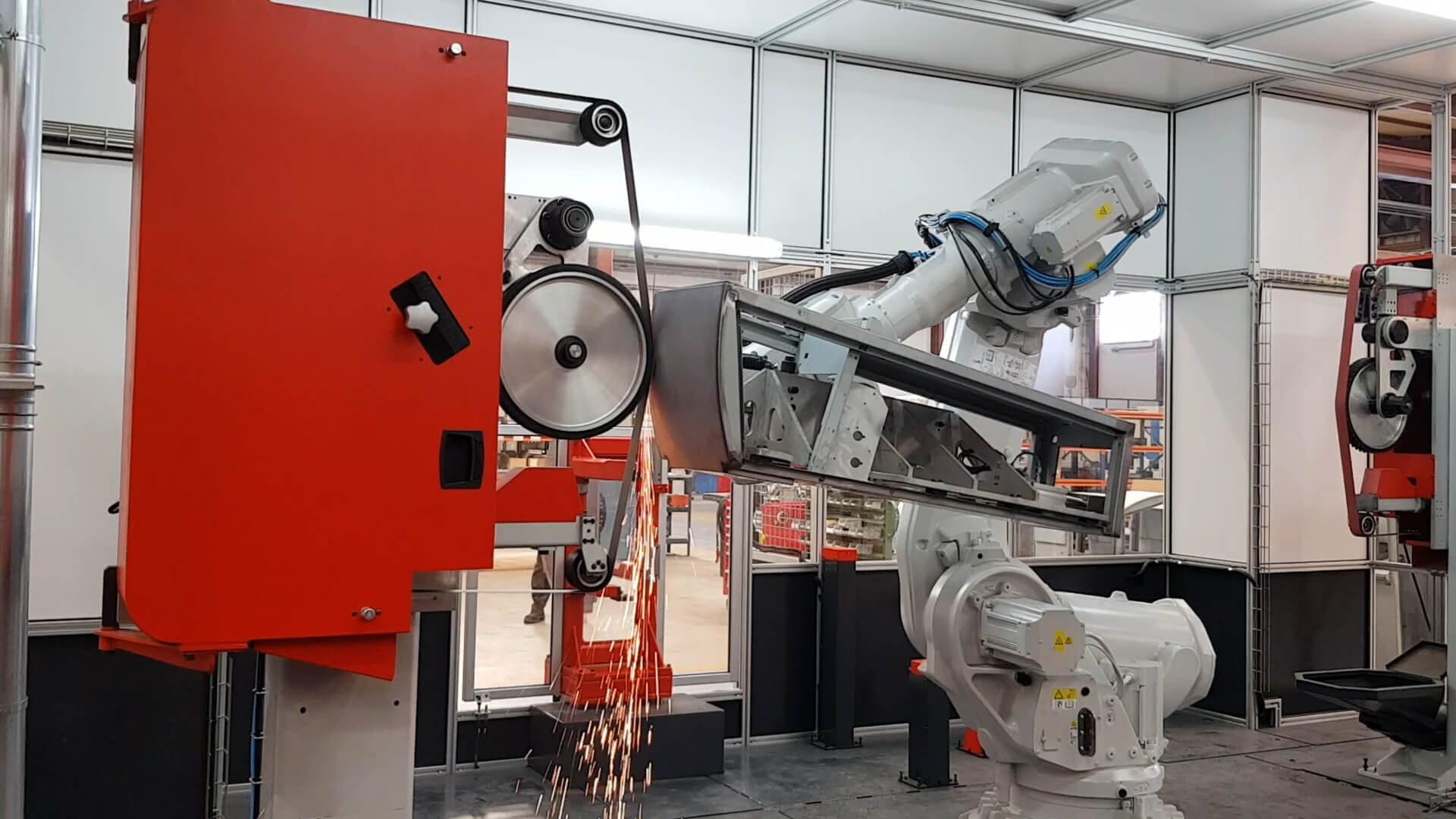

Automation should always be part of the discussion when looking at costs. From increased volumes to greater consistency and more efficient use of labor its adds up. A simple example I like to use is that a welder who spends half of his day grinding is just not efficient. A welder wants to weld not grind so you face turn over and retention issues. Not to mention you are paying a skilled welder to weld and that is what you need them to do. Any time they spend grinding is not an efficient use of labor or resources in general. Taking finishing tasks to automated processes resolves many of the issues that that situation brings. It can make production of a given product more competitive. Having the welder free to weld means a higher and more efficient flow of product. Being able to deliver faster lets you take advantage of demand and sets you apart from others.

Keeping the production in place and being more efficient would seem to make sense on several fronts. There is no one size fits all answer and what works for one may not for another. One of the steps to keep manufacturing in North America is going to be automation. Many are getting into robotic welding now. With that you still need to finish the welds and remove the discoloration from welding. Automating the finishing aspects helps you get the most from the robotic welding. Having a process to take the welded parts and quickly and consistently do the finishing work frees up the staff to keep the welder running. It also cuts out the finishing bottleneck. You need the finishing to at a base keep up with the welding. If you can weld the part faster but then you have to stack the parts waiting to be finished did you get all you could from the robotic welder? Increasing the flow of product while reducing the cost per part would seem a perfect situation.

Re-shoring manufacturing back to the USA, near-shoring it to Mexico or just keeping it here in the USA relies on some basic business principles. Do it smarter, faster and better than your competition, and make it profitable! Depending on the type of industry you are in, the benefits can be huge or minimal, but usually when combined make good business sense. Reduced supply chain costs, manufacturing and distributing in the same region reduces shipping costs and helps mitigate against complicated and time consuming supply chains. Faster to market, less time on the water and faster from R&D to production and on to end users. The goal is to look at efficiencies in both manufacturing and distribution to make the strategic decision of manufacturing in the USA logical. Automation is one of the greatest assets in improving efficiencies, but what and where in your facility? This is where you should seek the help of someone that knows automation. Also know there is no silver bullet and no one sizes fits all solution.

Automation should not be feared but rather embraced. It is a way to get a handle of production costs and improve quality and volumes. Younger people take to automation very quickly and have little trouble. You can leverage younger staff that were born into that higher technology and let them shine. Know that often it is automation you are up against rather than cheap labor. Taking steps to get ahead of this falls into the situation of an ounce of prevention is worth a pound of cure.

Please feel free to send in any questions you have as every situation is unique.

Topics tube finishingcost of operation comparisonmetal finishingwheelspolishingweld grinding