One of the sticking points you will likely run into is how do you know what you need? Finishing is what we know so we are going to stay on that branch of machines here. Many of the general concepts will apply to all manner of machine but finishing is the topic here.

There are some more basic questions that are best answered up front. They can each help to define what you need and in some cases if you need anything at all. With these answers you should have a good idea of what you need and what you don't.

Volume: How many parts do you need to do? If you need to process 20 parts that is a different path than 2000. You should look around the facility as a whole and don't let yourself get too focused on one part or area. Yes there is a specific part driving you crazy at the moment but keep in mind other parts that could use the same or similar work. With this number add a little to give you some room to grow and you have a volume number.

Part size: What is your typical part size or range of sizes? If you only process parts that are 4" x 4" there is no real need to get a machine 60" wide. But if you process parts 36" wide you may benefit from a wider machine. Knowing part size helps to figure out machine width and to some degree machine type.

Materials: Knowing what material types you need to work with plays into several points. If you only work with aluminum you wont benefit from a magnetic table as an example.

How do you produce your parts: Laser cut parts can be a lot different than parts cut on a plasma. Knowing how the parts are cut will help to guide you to the correct tools and capabilities.

What do you need to do to the parts: Knowing what you need to do or what the end result should be is key. Do you need to remove a bur only? Do you need a grain or line finish? Do you need a good key for paint to stick? A machine to produce a line finish will not be the best option if you need to prep for a coating.

Now lets take some of the answers you gathered and apply them to an example situation. We are just going to look at the answers and what machine that would point us to.

You work with 600 parts each shift.

Your parts range from 3"x3" to 30"x30" and it is always a mix of sizes.

Its steel and aluminum both at 50/50 consistently.

Parts are cut on a laser and the cut quality is pretty good with occasional cut issues.

In this case you need to prep for powder coating the vast majority of the parts.

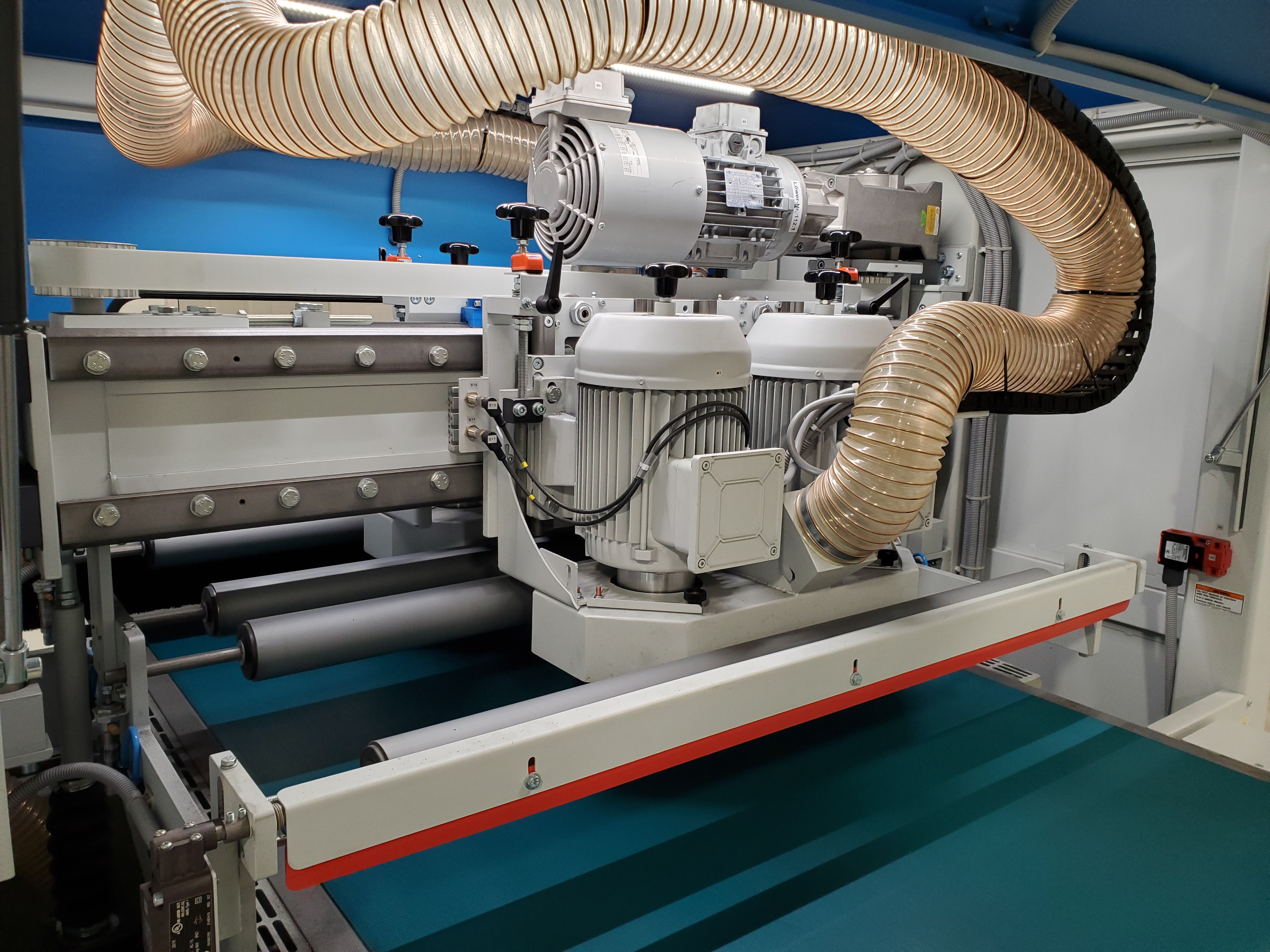

In this example case there is a clear direction to follow. With the smaller parts and the mix of materials a sanding belt is out. The small parts will never stay in place with the sanding belt likely to throw them. This point is supported by the need for coating prep, a belt would leave too deep of a scratch that is likely to show though the coating. So we know we don't want to use a wide sanding belt so far. We also know that a 60" or more machine is not required as the largest part is 30"x30". So we are going to look at a 40" wide machine. Parts being cut on a laser means the bur will not be extreme so we don't need to get carried away with tools. You need to push the bur over and remove it. Getting some edge rounding would also help to avoid the coating being thin on the corners so we want to add that in.

With this you know you need a machine around 40" in width. You know you don't want a wide sanding belt and you do want some edge rounding. A machine like the 4TD-1000 would do this task very well and keep the operating costs down. For this application it checks the boxes so to speak. Its 40" wide, has no wide sanding belt, can deal with the vertical bur and can give the edge rounding. You get what you need with out added tools or working width you do not need. This would keep the cost and floor space needed down compared to other machines.

In the example going to a machine like a single wide belt or even a belt with a brush of some fashion would not have been the correct choice.The smaller parts would likely get thrown by the wide belt. But as any of the answers change so can the machine needed. If you only process steel as an example but all other parameters stay the same, In that case a magnetic table may get you around the small part limits of a wide belt making it an option. If your smallest part was 18"x18" then you would be able to more safely work with a wide belt. So as the answers to the questions change the machine will often change.

By asking the base questions and applying those answers you are able to focus in on what you actually need. Its also helpful to anyone you are working with to know these answers as well. The goal should be to get what you need and not waste money or space on things you don't. There are many other points that can be a factor but these would be the base starting questions to get the ball rolling on a project. We are always here to answer questions and help how ever we can.

Topics deburring machinedry deburring machinecost of operation comparisonSmall Part Deburringgraining sheet metal