Many times companies will ask about a machine they saw online and want to know some basic information. They get that basic information and head down the path of finding some version of that machine. They might look for a larger or smaller version or one that works with the power they have available. But what went wrong is they never asked if it was what they actually needed. When you go to buy things its not often you would get asked about your reasons for looking to buy something. If you went into a shoe store to buy a pair of white shoes that is what you are there for and no one is likely question you.

When it comes to machines the reality is that you want someone to question you. Back to the white shoes again, if your plan was to go hunting a pair of white shoes may have been a bad choice. Could be a pair of boots or some other color shoes would work better but you were never asked. With machines this is often the case and being questioned a bit is what you want.

So what are some of the questions or topics that should be looked at? There are so many as it is different for just about every situation. But there are some that are a bit more universal.

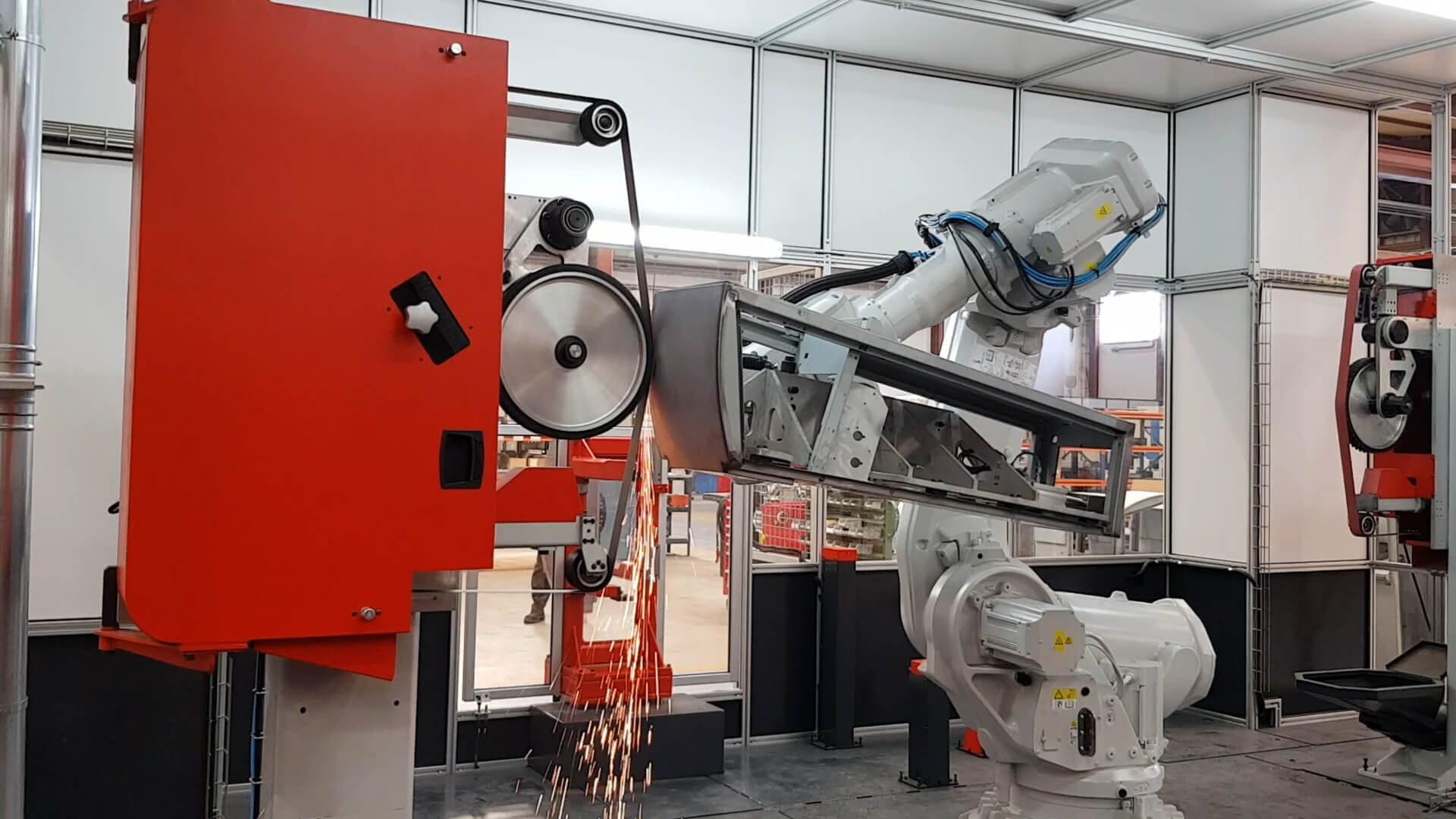

Volume should always be looked at. No matter the problem the volume of the problem matters. If you have a given part and you make 2 of them a week lets say. But on each of the parts you spend 3 extra hours with them removing scratches. It is a real problem and you are eating 6 hours a week. But there are so many ways of solving the issue that the volume question matters. There are robots that could sand out the defects in 3 min per part or less. But that could cost half a million or more. If you don't add the volume information to the problem you will get bad advice. Being offered a heavily automated solution for a half a million will seem ridiculous to you in this case. But if you don't provide or have the volume information it was a reasonable solution to offer. With a low volume of parts heavy automation generally will not make sense. A lower cost option that has more flexibility would likely be a better option in this case.

Determining what you need to accomplish and the problem you need to resolve may seem simple, but it is more challenging than it appears. This complexity is further compounded by additional questions and information. Merely saying, "I need to cut aluminum," is not sufficient in this case. Do you require the ability to cut 0.04" or 1.250"? Are you solely cutting aluminum, or do you need to work with other materials as well? It is crucial to have a clear understanding of your goals and requirements at the top of your check list.

Budget, the reason this matters is it will save you time. A great solution that checks all the boxes but is 3 times your budget is not going to work. Knowing the budget and sharing that information allows you to focus on solutions that work with in the budget and not waste time looking at things that are outside your parameters. This would go along with the ROI conversations as well, if you need the payback to be 24 months or 6 months it ties back to the budget question. Knowing this and sharing that information saves time and gets you to the answers that are best for you more efficiently.

There are other issues like floor space and what the complete process is for your parts. Do parts get painted or welded as that will have an effect on what might work best. Do you have a process now that needs updated or replaced or is it a new process for you? These are some of the many other points that should not be neglected.

Digging a bit deeper into the situation and talking with someone will help greatly. While you should look at videos and machines, know that what you find will only be a percentage of what is out there. Things can and do change so be open to suggestions or alternative ways to get where you need to be. We are always happy to help and provide advice on your specific situation. Please feel free to contact us if you need help resolving any type of finishing problem. We will ask you these questions and many more to be sure you get what you need.

AM Machinery Sales

Topics metal deburring machinemetal finishingpolishingweld grinding