With so many facilities working with round tube, it seems that giving a little information on how to finish round tube would be helpful. There are all manner of ways people have come up with but there are safe and easy processes you may not know about. I am not going to go over every possible way but rather focus on the safe and simple.

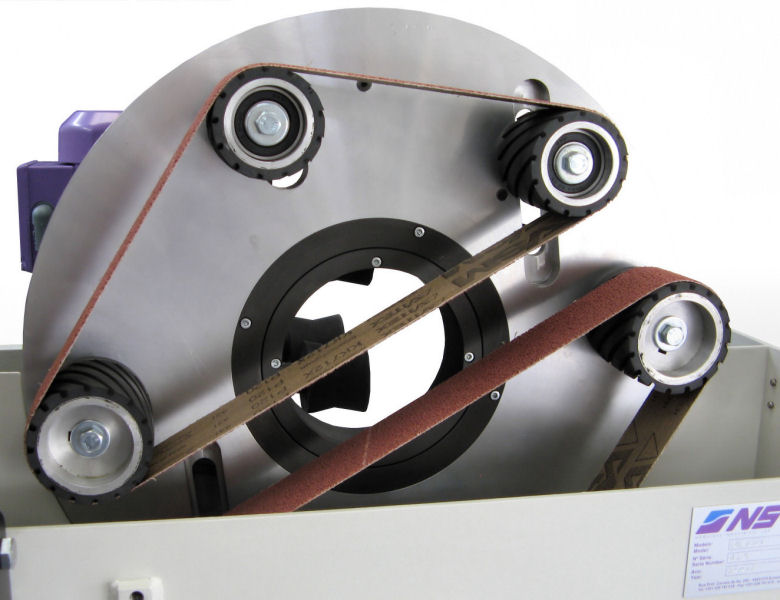

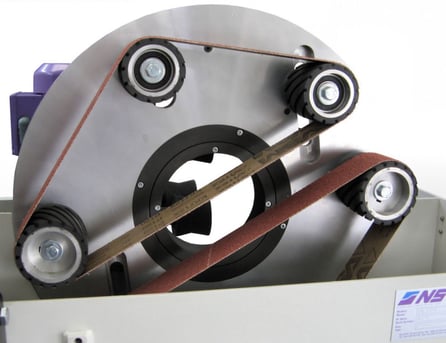

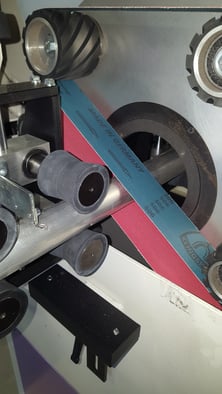

The planetary style of tube processing machine is that safe way. As shown in the image above there are two identical sanding belts with adjustable positions. The tube passes between these sanding belts as they spin making contact with the surface of the material. Now that motion alone would just put two flat spots in the material so the complete planetary wheel they are mounted to spins as well. This provides full coverage of the parts surface giving even contact.

With the material processed in this way it allows the tube to be held firmly and not allowed to rotate. The fact there is no spinning of the tube makes it much safer versus many other ways of finishing tube. With this style of processing any small bow in the material is not dangerous to the operator or the people around the process. With many other processes that require the tube to spin there is a sizable risk to the operator if there is a bow or bend in the material. The bow will often send the tube into a flailing motion like a bucking bronco.

With the material processed in this way it allows the tube to be held firmly and not allowed to rotate. The fact there is no spinning of the tube makes it much safer versus many other ways of finishing tube. With this style of processing any small bow in the material is not dangerous to the operator or the people around the process. With many other processes that require the tube to spin there is a sizable risk to the operator if there is a bow or bend in the material. The bow will often send the tube into a flailing motion like a bucking bronco.

By holding the tube firm and not allowing it to spin you remove the risks related to the material having a bow or bend. It allows you to finish less than perfect material so you end up with fewer rejects.

This setup also allows you to produce any finish you need on demand. If you need a #4 just fit some 120 grit belts and off you go to a #4. Need to knock off rust quickly just fit some 60 grit belts and job done. You get any finish you need and when you need it with just a 30 second belt change.

The video above gives a walk through of the machine and how it works. Safe and simple is the key with this style of processing. There is no set finish and you have complete control to change it at any time. The machines will run any manner of sanding belt including scotch brite. Make any finish you want when you want it and safely. With an automatic feed on many of the machines feeding even 20ft lengths becomes simple with a consistent finish over their full length. These machines have proven themselves to be reliable work horses with many purchasing several units.

If you need to finish tube its hard to beat the planetary machine. They are far safer than other options and can make any finish you need when you need it. Even bent material can be processed with some limitations. If you need more information on one of these great little machines just let us know.

Topics tube finishinghands-off tube finishingcenterless or planetary grinding systemmetal finishing