A question I get often is robot vs CNC for finishing work. While there is not a clear yes or no type answer there are a few points that can help to guide the person faced with the question.

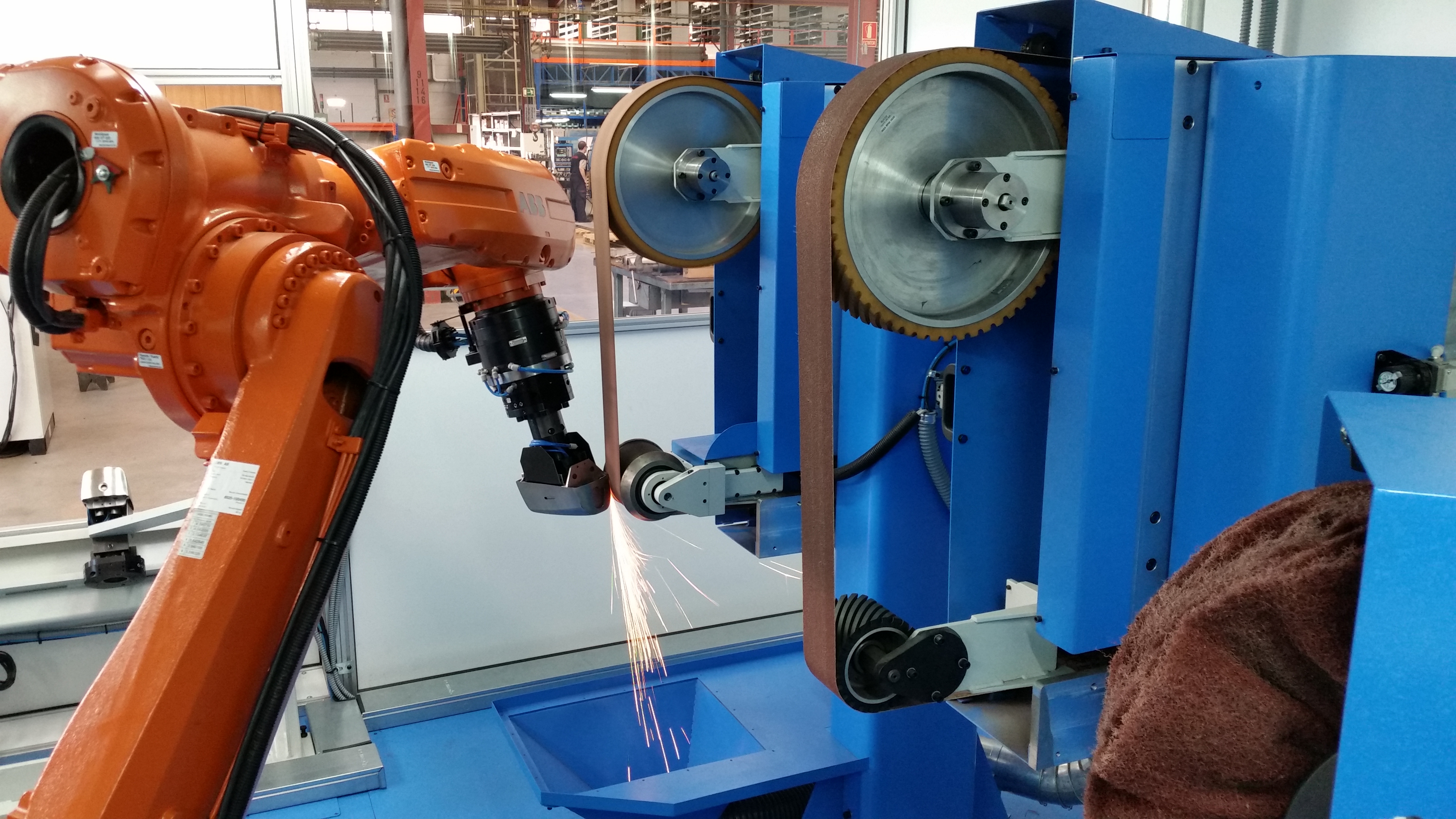

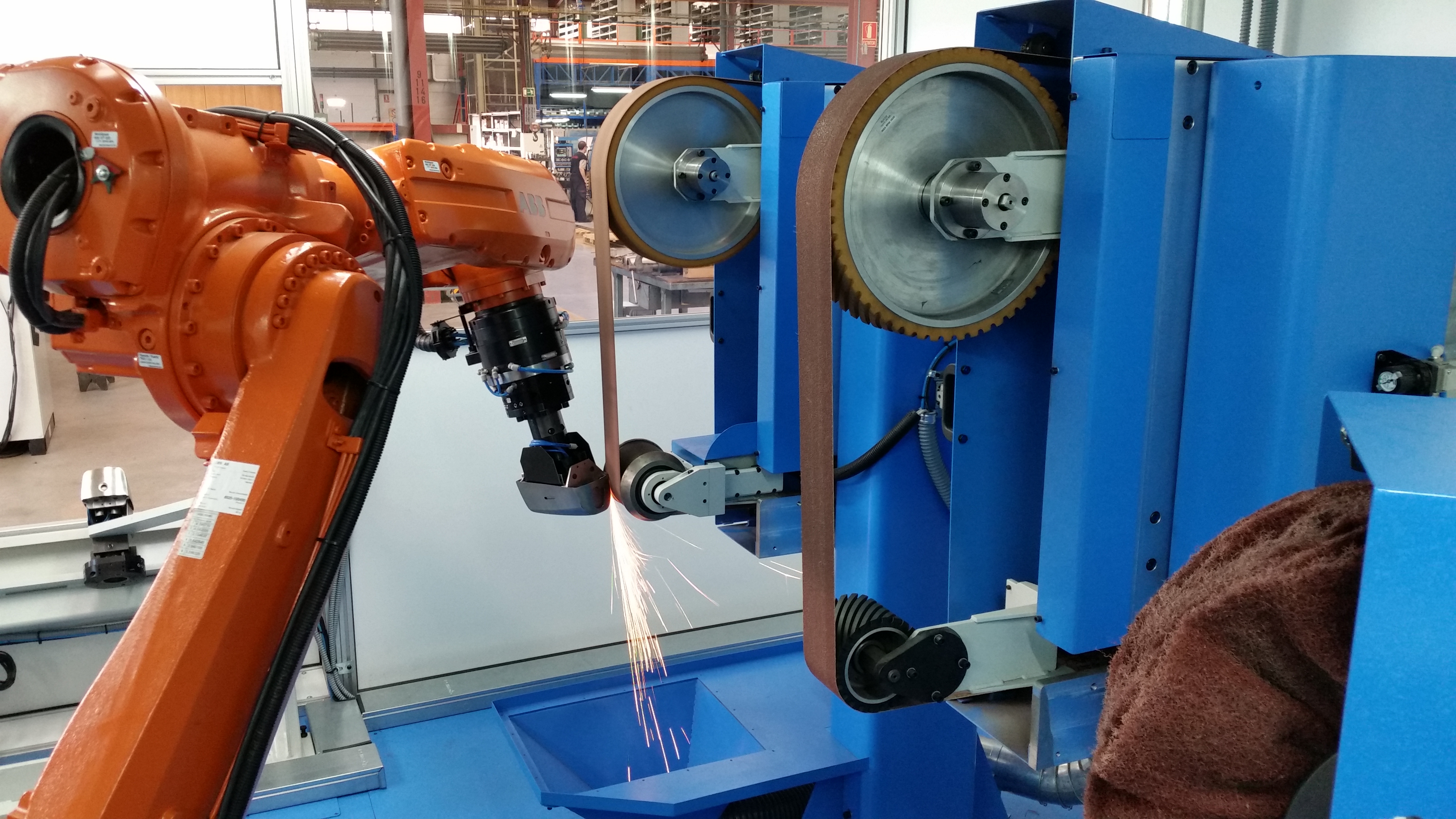

For detailed parts a robot tends to be a better choice. The precision movement you can get with a robot allows the detail work on a given part to be done much more easy than CNC. Tool flexibility also tends to be better with a robot for a number of reasons. From standard sanding and buffing to detail carbide cutter work the robot can do it.

If raw speed is the main need then look to CNC. Multi station rotary machines can bring raw speed to the process mainly with polishing work. If you need to polish wheels the added power and speed of a rotary is very hard to beat. Producing a fully polished wheel in 60 seconds is possible with a rotary system. You can be much more aggressive with a CNC when polishing vs other options and get a deep clear finish.

CNC tends to be easier to live with long term due to the design and build of the machines. A more simplified interface allows a person with basic computer skills to program a CNC. You will not need a dedicated programmer to interact with the machine leaving you with more options on operation. A person that knows polishing and has basic computer skills makes for a very good operator.

While not as easy as the CNC robots tend to come with a user interface that simplifies the interaction. The main thing here is to be sure you have full access to make and edit any programs. The interface brand to brand and machine builder to machine builder is not all the same so be sure to look into it. The best advice here is to not ask the machine builder to do all of your programs. While they can do it that will leave you at a disadvantage long term. The steps of making and testing initial programs is valuable learning time that you do not want to pass on. While it will not be smooth sailing having assistance while you make the programs leaves you in a stronger more capable position for the future.

Sanding in general is better done by robot. The flexibility in tools or back stands allows you to do more with less. Polishing is better served by CNC where you want to be a bit more aggressive and reduce time. The main point is to be involved in the early stages and do not pass on any opportunity to learn or do. And do not forget that every process starts where the raw material enters the building. Any defect carried in on the raw material just gets compounded as it moves through the process. Have clear goals and work with some one that has experience to get off on the right foot.