Polishing, you love it and hate it at the same time just like everyone else. I still think brushed finish exists due a person somewhere getting fed up while polishing and giving up, "That's good enough my arm hurts" is what I bet was said.

The mesmerizing shine of a mirror-polished finish may leave us in awe, but we rarely stop to ponder the effort and hard work that goes into achieving it. Indeed, mirror polishing is one of the most challenging finishing techniques, applied to a wide range of parts from door handles to hip joints. The process typically involves a long line of fixed back stands, each manned by a worker toiling away in a dirty, strenuous, and unglamorous job. The physical demands of polishing can make it difficult to staff, and the inconsistencies that arise from multiple people working on the same task can make it even harder to achieve uniformity. In short, achieving consistency in mirror polishing can be an uphill battle. Nonetheless, machines exist to tackle the dirty, dangerous, and hard-to-staff jobs that humans find challenging.

Automating the polishing process not only guarantees consistency and speed, but it also liberates the staff to focus on value-adding tasks such as quality control. Furthermore, the expertise of the staff can be preserved and stored in machines for future use, thus mitigating the potential loss of knowledge due to employee retirement as an example. If you take that experienced person and have them involved in the programming all the tricks they have learned can be shared with the machine. It can often be small details that make the largest difference and you only learn them with experience.

CNC style machines exist to do heavy polishing work when you need power and speed. They have the brute strength to drive large buffs to cut the surface quickly. But when you have finer or detail work that is needed the robot comes into its own. Precise movements on complex geometry is where robots make sense.

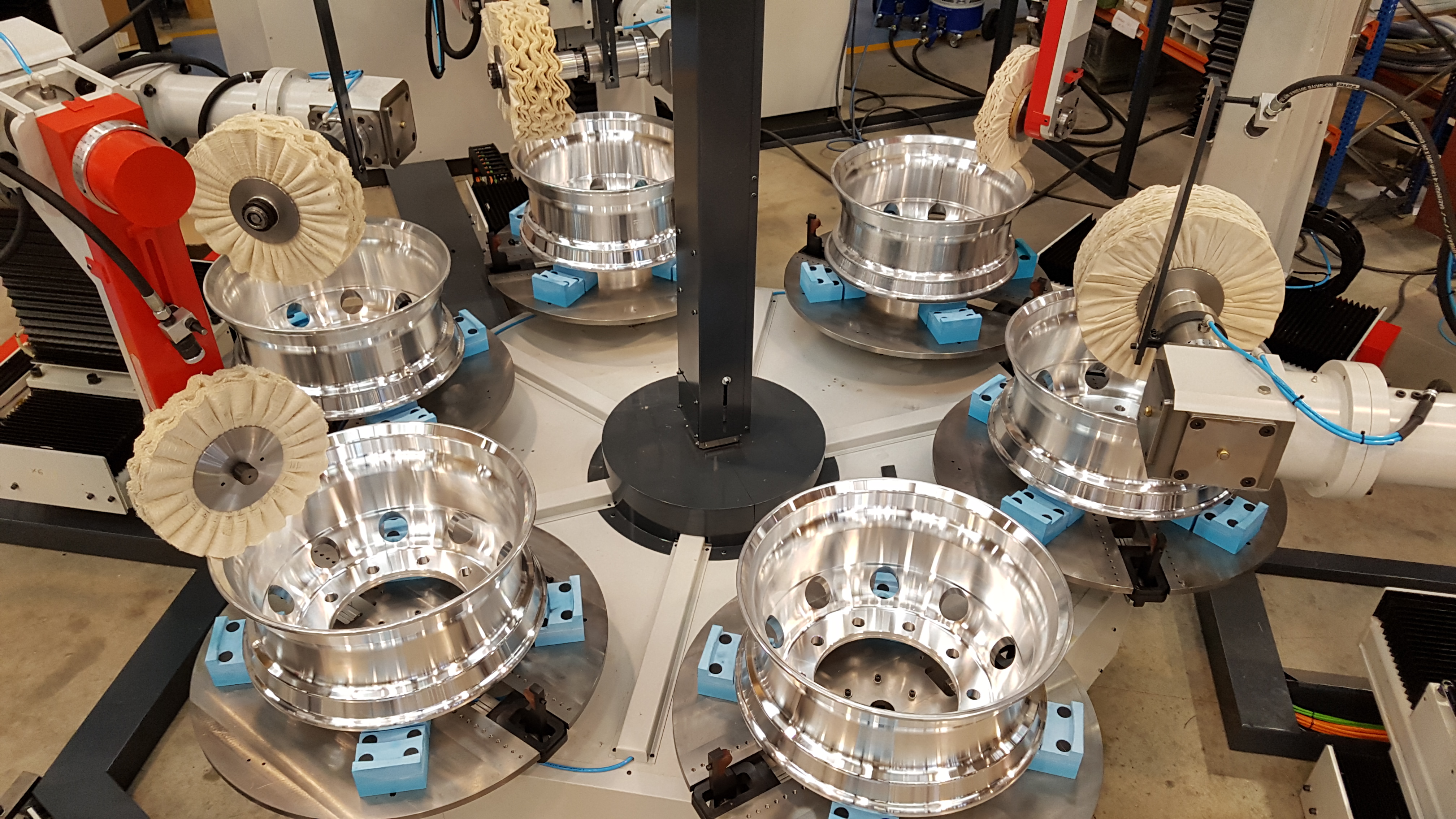

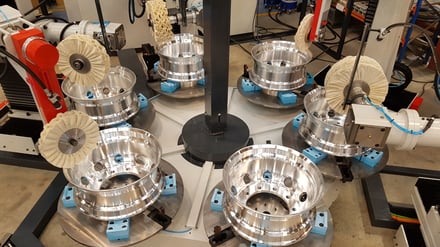

As an example wheels are polished on a CNC.

When you need a lot of wheels and quickly its the best option. Getting a 22" wheel finished in 60 seconds per side is what these machine do every day.

How about another example?

That is a brush finish going on to a subway car. If you ever wondered how it was done now you know. You can finish just about anything if you work with the right people.

One more,

Fabricated sinks where you need to get the welds down inside the parts. A CNC can do that level of detail when it makes sense.

With a plethora of finishing options available, it can be overwhelming to decide where to start. But fear not, for there's a simple solution - start by asking questions from everyone. Talk to your staff about bottlenecks and issues that need addressing. Reach out to machine builders for guidance. A reputable builder will be able to recommend the best option for your specific needs. As experts in finishing for over 40 years, we've helped countless companies overcome these very challenges. We look at the parts and listen to your needs to help find the best solution. We welcome the opportunity to look at your situation and offer input on what options would work for you.

As always feel free to ask questions we are happy to help.

Or visit Our website

Topics metal finishingwheelspolishingautomotiveweld grinding