We often get asked about tube finishing here. Tube is one of the materials that seems to be in every shop but no one notices. Some tasks with tube can be super simple and others can be a real pain in the butt. So to keep it short lets look at working with basic straight lengths and some bends.

With straight lengths the need is often defect removal or the application of a finish. Pre-finished material can be costly and a pain to store with out damage. One of the simple ways to deal with this is to finish the tube as needed and just by the cheap stuff. There are compact machines that can do this with out breaking the bank or being some risky operation that puts staff in danger. You can use lower cost raw material and put on the finish you need when you need it.

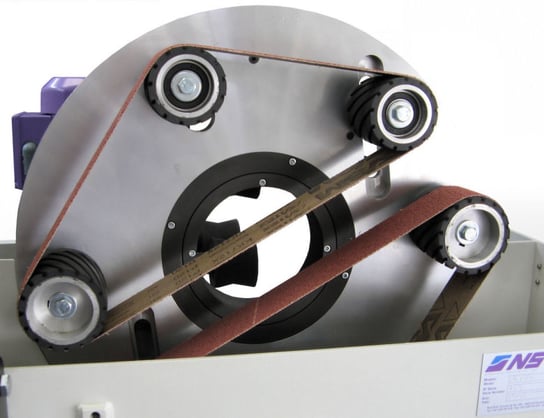

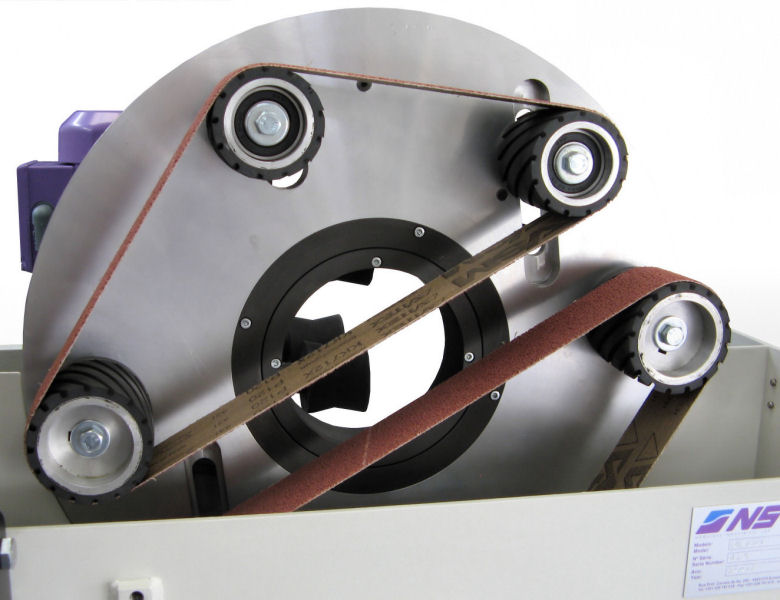

Planetary finishing:

With this style of system the tube is fed through the machine either by hand or with an integrated feed unit. As this machine will not spin the tube it is far safer than other options we have all seen. You get a simple process that can put the finish on your material with far less risk to staff and they are super simple to use. As they use a pair of sanding belts, you can fit any grit you wish. This means you can make any finish you need from a coarse 60 grit to remove rust to a fine scotch brite and anything in between. This means you can hold stock of standard unfinished material and put on any finish you need. Not being limited to any finish means if your needs change its no issue, You can just change the sanding belts to match the new need and you are all set to go.

Bent material:

Another great function of the planetary is that it can do bent material. It is one of the few systems that allow for the easy swap between straight and bent tube. If your bender is leaving marks they can be taken out by the same system that applied the original finish. This takes away any chance of the finish not matching. There will be limits as to how tight of a bend you can process as it needs to fit through the machine obviously. But the vast majority of bends tend to pass right through the machines.

You can get a compact simple to use machine that will finish your round material and have it up an running in no time. The most common size of machine we tend to have in stock no less so you don't need to wait. You can be finishing up to 4" OD round material in a week. The machines are 208/230 volt so power is not an issue with a low connected load.

Aluminum, Stainless, steel nearly any round material can be processed up to a 4" OD. Remove a weld seam or put a nice finish on hand rail in the same unit by just changing belts quick and simple. What ever finish you need and when you need it in a compact simple to use package.

Topics tube finishingcenterless or planetary grinding systemmetal finishing