Small parts are one of the challenges most shops face at some point or every day in some cases. They can be tough to manage and tend eat up a lot of time while in some cases being dangerous.

Most will try to send them through the old belt sander first only to find they don't tend to stay put on the feed belt. Then there is tumblers, small bench top sanders or the ever handy DA or palm sander. So then you look for better options and you will probably find some one saying a vacuum table is the silver bullet. There are cases where the vacuum tables can work and do just fine but that tends to not be the rule. The biggest issue is air flow in general. If the feed belt has say 100 holes in it for vacuum and your part only covers 10 of the holes there will be no grip on your part. The air will just flow to the open holes and now your part is just on a feed belt with holes in it. The second issue is the same 100 holes are pulling air as well as the sanding debris. That means you have to keep up with the service side or the ports will just get blocked with debris. So there are clear issues with a vacuum table that are very tough to get around and you have to be diligent with the cleaning and upkeep to keep the system working.

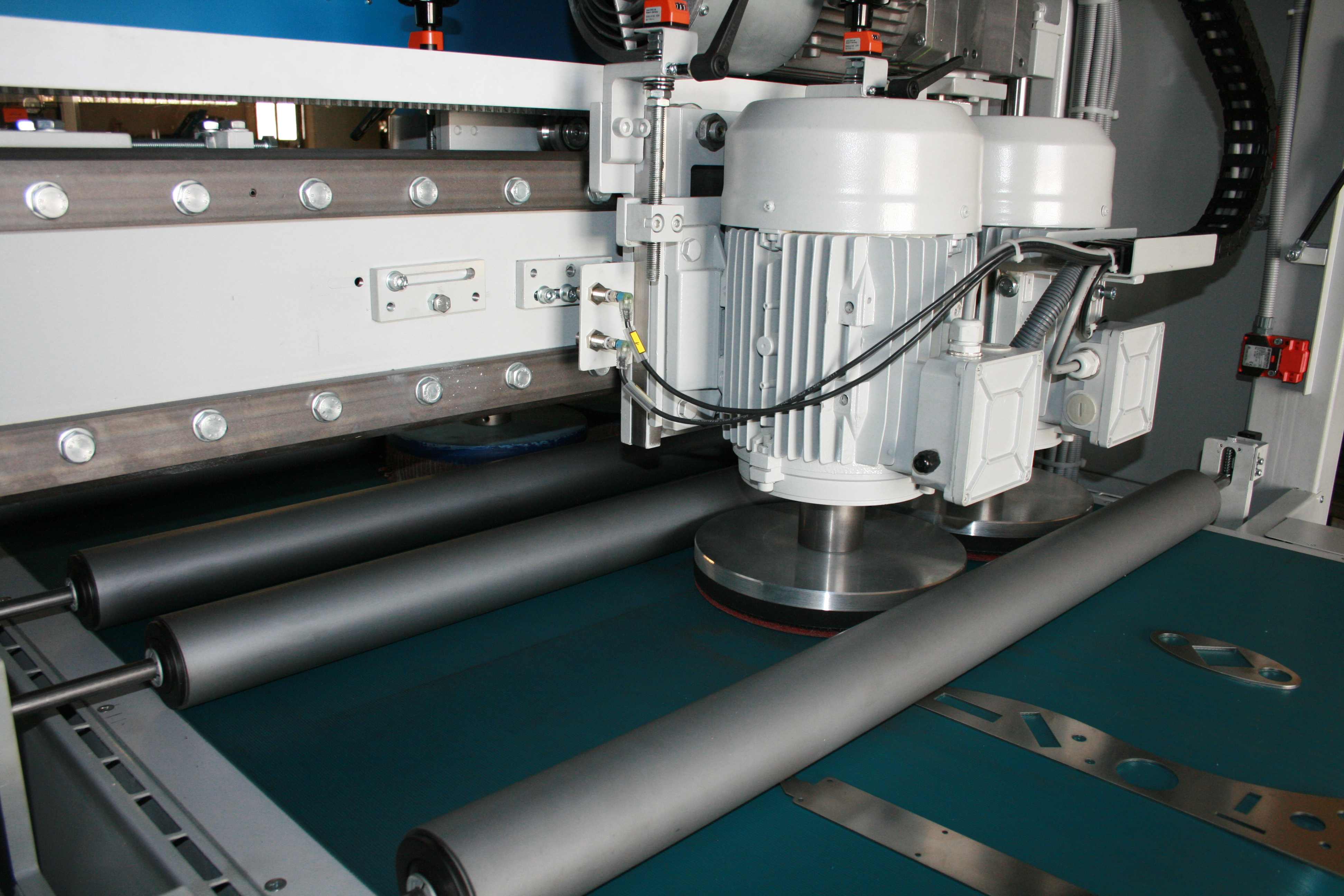

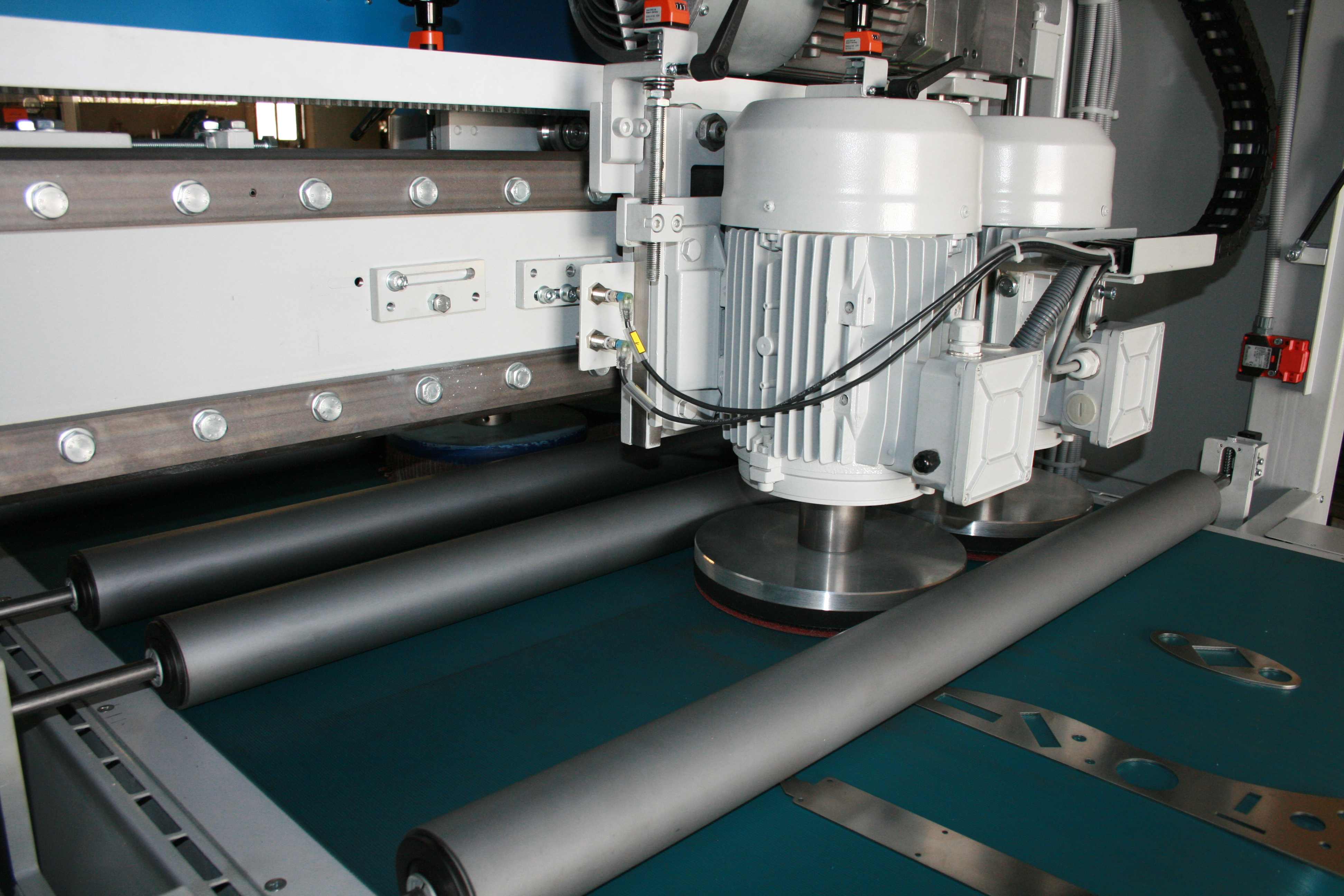

When you put a small part on a rubber mat and use a DA or hand sander the part tends to stay put. What helps make this happen is you are pushing down on the part and pressing it into the mat. With a belt sander you are applying a lot of pressure to a small area and it is attempting to push the part along the feed belt. This is where a lot of the thrown parts come from. Changing your approach to the process and looking at machines that press the parts down into the feed belt with brushes or other tools makes sense. If the same concept works when you do it by hand its should give a good indication of what to look for in a machine. There are more sides to this and I have only skimmed the surface. You can use magnets if your parts are ferrous or even fixtures but they have their issues as well. Small parts can be tough but they are absolutely possible to do in a through feed style machine.