This Twin Belt Grinding Machine, better known as a Stroke Sander, is built for the roughing and finishing on welded edges and corners, flat surfaces of steel, stainless steel, and aluminum, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft are typical applications.

Stroke Sanders have been around as long as I can remember and I have been in this business for 45 years. Like everything else, they really have changed over the years and have greatly improved. But before I get into the improved models of today, be advised you can still buy a single belt machine just like you could get 45 or 50 years ago.

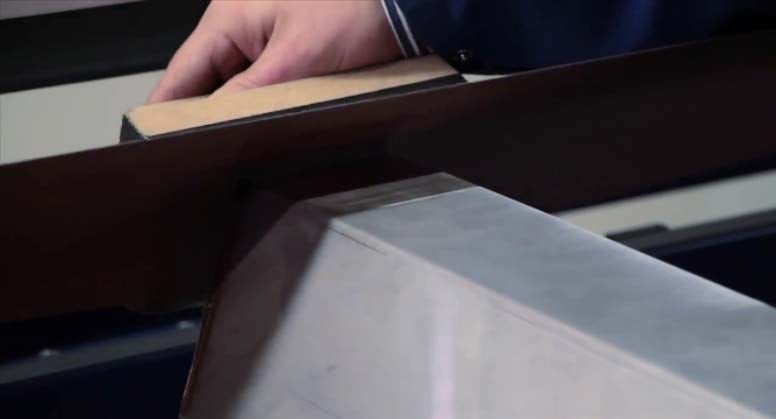

Today’s stroke sander looks different but still work the same as years ago, The top of the machine today has a pyramid shape to allow the operator to see the work as he is processing it. Most machines have 2 abrasives to work with. This allows you to remove welds quickly with a coarse belt and then finish grind with a fine or a scotch belt.

In the past an operator would take a box, for example, with welded corners and stand it on the table and rough grind all the welds. This was not a problem if you were grinding a square box. Then he would change the belt and repeat the process and finish the part. You can imagine all the material handling and time this process would take. Today, you can get a vacuum device to hold a box up to 250 lbs., rough grind and finish the box before removing it from the machine. You can also get a machine with a CNC control to automate the finishing process.

It is estimated a savings of approximately 50% on working time by the use of the 2 separate grinding belts for roughing and finishing: Only one handling and setup of the work piece. Further savings of approximately 25% by use of the handling device: The work piece can be orientated on 5 axes and can be prepared on all sides in one operation. Power table height adjustment variable speed control conveniently located within operator reach has also simplified the operation of the stroke sander machine.

Follow the link below to see a full video of the KBM unit.