You probably know basic deburring machinery technology. We would like to point out a few things so you can appreciate how the old technology is still being used, but improved upon, to provide better edge quality as well as savings on your manufacturing cost.

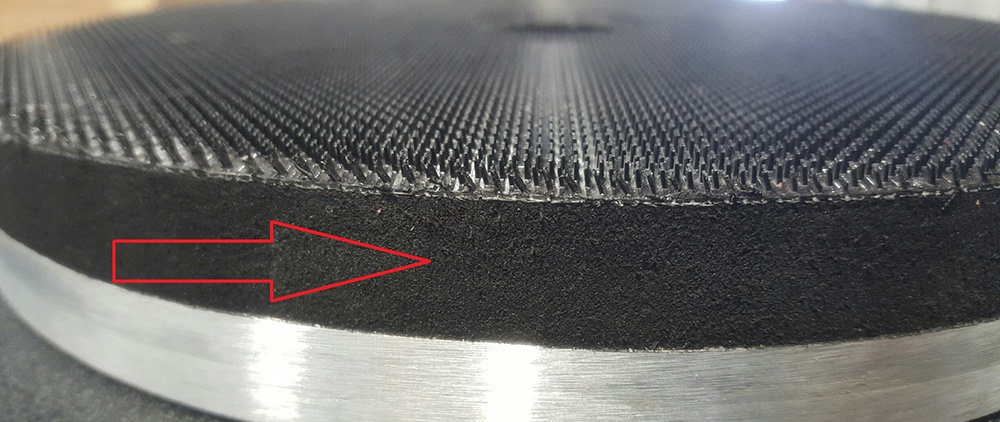

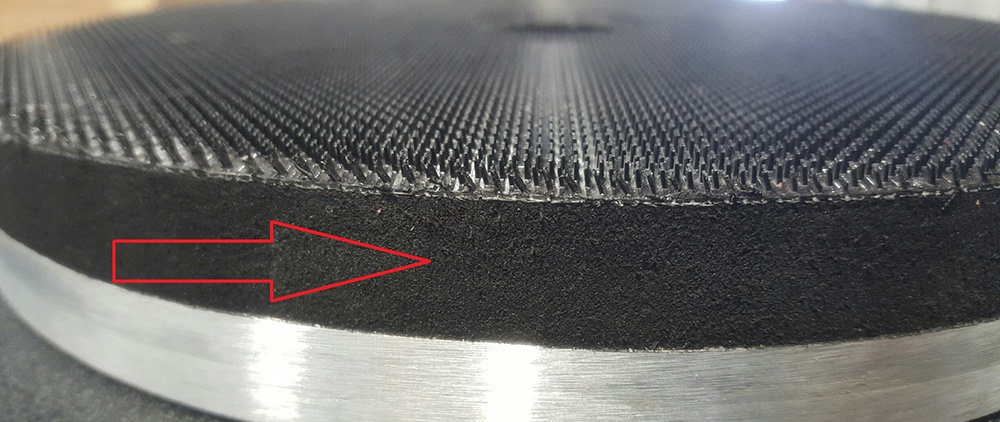

First, the Loewer deburring machines use many of the same basic principles that a wide belt machine uses. For example, if you look at the disc that the abrasive attaches to, you will notice under the Velcro there is a rubber pad. These pads come in different hardness just like a contact drum, only the disc is much easier to change and a fraction of the cost of a contact drum. You can use harder rubber to be more aggressive or softer to allow the abrasive to flow in and out of holes and edges. It is still critical to know that speeds and feed rates are the key to getting the best edge quality possible. This is why all Loewer deburring machines come with variable speed and feed and oscillation stroke.

Since we are talking about contact drums, we believe this point should be easy to understand - we get a much better edge rounding than our competitors. If you look at the point of contact of a drum machine you will see the abrasive only makes contact for a split second. In a Loewer machine, the contact time is continuous for the entire time the part is under the abrasive, continuously being worked on from all angles and directions. In addition to this, a contact drum will apply a lot of pressure in a short area and it will shoot the part through the machine like a bullet unless it’s held by pinch rollers or in the case of small parts, a fixture. Here again the disc design doesn’t have this problem and, in fact, is able to process small parts without fixturing.

We Do Not Grain

One of the objections most customers throw at us is that we don’t grain in our machine.

This is true, but we would like to point out a few things for you to think about before discarding Loewer for this reason. We have sold many different machines for finishing including machines to steel service centers for graining stainless steel and applying a number 4 finish. You probably have bought stainless sheet material with laminate paper on it already, so you know the finish on this material has an esthetic value. You cannot match this finish in a wide belt machine no matter how many times you run material through the machine. This is because of how the finish is originally applied.

We recommend you purchase prefinished material with quality laminate paper on it. When you punch holes or laser cut this material you typically cut through the paper first leaving the burr on the bottom edge, so deburring is not a problem. In some instances, you may still need to deburr the paper side of the material and this is not a problem with the Loewer machine. We can deburr without removing the laminate paper.

Please contact us for further details on how the disc works to your advantage

Topics Loewer Deburring Machines