This is the fourth and final series of blog posts on tube finishing. Click on these links to read parts one, two and three.

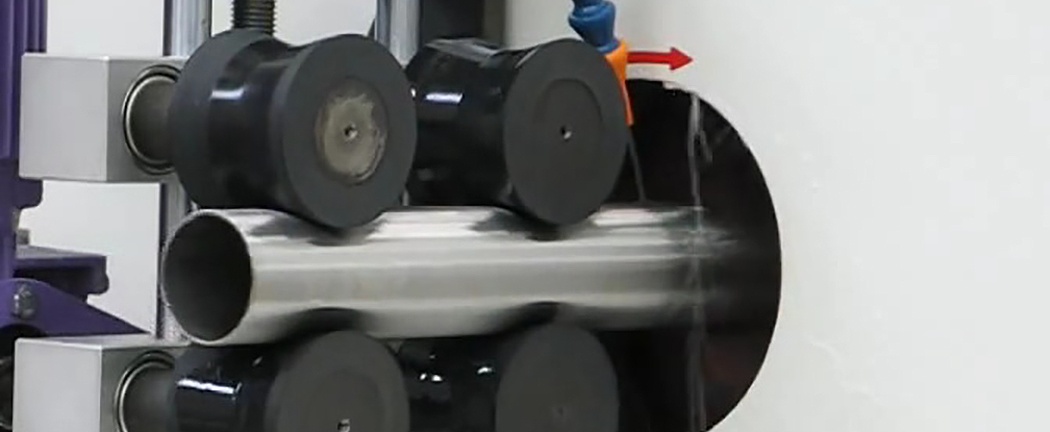

When comparing centerless and planetary grinding systems, remember this fundamental difference: With a centerless system, the machine does the work of carrying the part through.

Once the part contacts the grinding and regulating heads, the part begins to spin rapidly and move forward. For the operator, it’s hands-off.

On a planetary system, once the tube is in the work area, the belts are grinding away, but the tube does not move. It is up to the machine operator to move the part through the grinding area, unless it is equipped with an automatic feeding device.

On a planetary system, once the tube is in the work area, the belts are grinding away, but the tube does not move. It is up to the machine operator to move the part through the grinding area, unless it is equipped with an automatic feeding device.

Both centerless and planetary systems offer varying degrees of automation. For the centerless machine, feeding is already a hands-off operation, so automation focuses instead on part loading and unloading.

In high-volume environments, a centerless machine can be fitted with infeed and outfeed tables to hold multiple tubes. Infeed tables often have pneumatic tilting devices that change the table angle in relation to the ground; this lets gravity feed tubes to motorized rollers that, in turn, present parts to the machine.

In high-volume environments, a centerless machine can be fitted with infeed and outfeed tables to hold multiple tubes. Infeed tables often have pneumatic tilting devices that change the table angle in relation to the ground; this lets gravity feed tubes to motorized rollers that, in turn, present parts to the machine.

Similar setups are designed at the outfeed, where finished tubes are collected and protected. As with centerless machines, automating planetary machines involves loading and unloading, but it also includes feeding parts continuously through the grinding area.

This can occur in two ways. The simplest is to fit the machine with an autofeed system consisting of two sets of motor-driven rollers above and below the tube at the infeed and outfeed. The operator loads and unloads parts, but does not manually feed tubes through the machine. Loading and unloading tables is available as well, but these options also require sensors (photo eyes) at the infeed and outfeed. The sensors instruct the machine to adjust the belts for tubes to enter and exit the work area. As always, which technology to choose depends on the application.

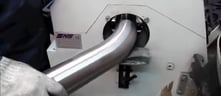

Centerless grinding excels at efficiently finishing straight tube. It also requires less operator intervention. Once the operator moves the tube into position, the machine takes it from there. Planetary systems do require some feeding force, either from an operator or external feeding mechanism.

But unlike centerless grinding, planetary machines can handle bent tubes and other irregularly shaped workpieces. Regardless, know that when finishing tube, hand tools are not the only option.

Whether you choose a centerless or planetary grinder, today’s machines can help make what was a difficult job much easier, safer, and efficient.

We hope you've enjoyed this series of blog posts about tube finishing. If you'd like to know more, please contact AM Machinery to learn about how we can save you money and time, and improve the overall finish quality of your tubing products.

Topics centerless or planetary grinding system