Sheet metal cutting and punching technology has made significant leaps in the last 50 years. But why hasn’t traditional abrasive finishing equipment been a part of that revolution?

That’s the question asked by AM Machinery Sales President Tony McCue in a new interview with The Fabricator, the official publication of the Fabricators & Manufacturers Association.

That’s the question asked by AM Machinery Sales President Tony McCue in a new interview with The Fabricator, the official publication of the Fabricators & Manufacturers Association.

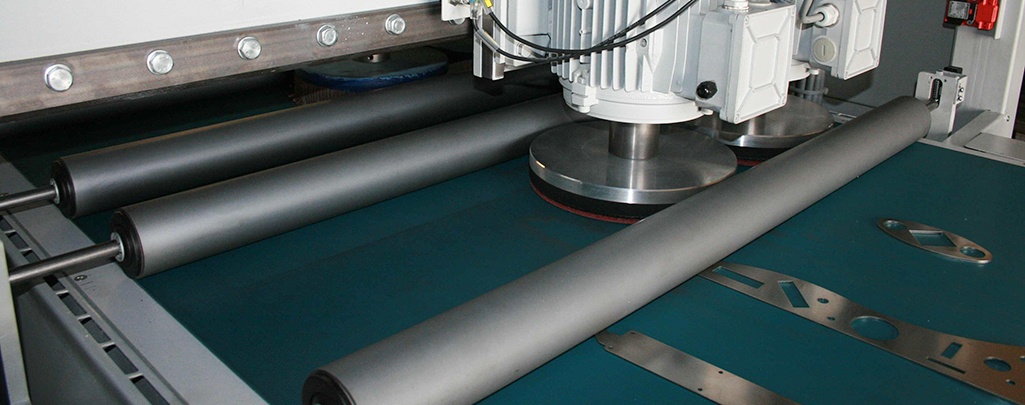

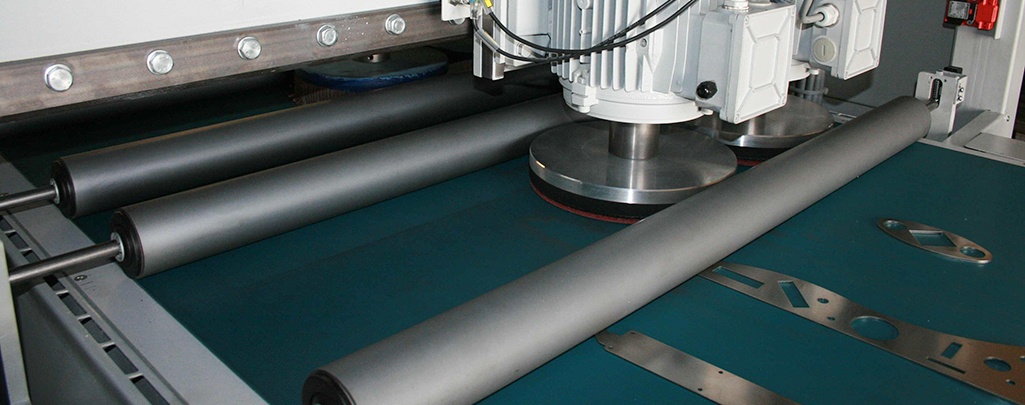

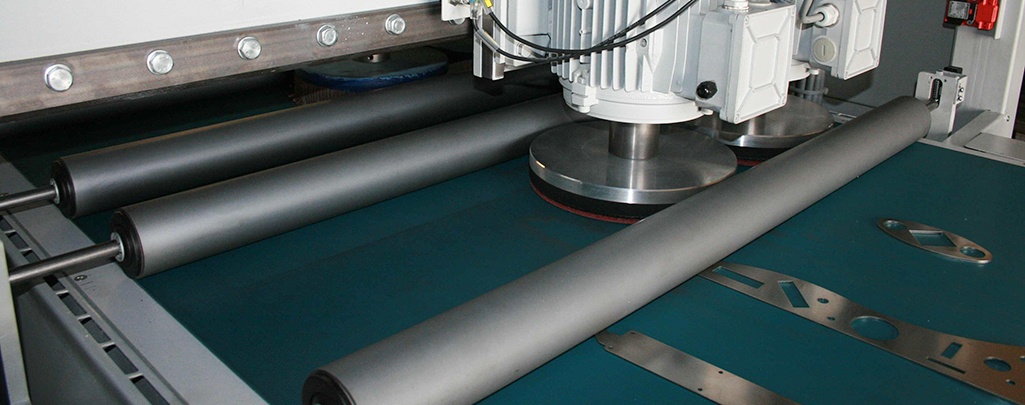

The type of wind-belt grinding machine Tony describes has been in use since the 1960s, grinding a metal surface as parts move under them.

But in the interview, Tony gives reasons why these machines can no longer meet the needs of modern metal fabricators, especially when it comes to laser cutting technology.

“Lasers can produce such a clean cut and square edge that the sheet metal parts can prove to be a cut hazard,” Davis writes. “The wide-belt machines simply dig into the metal, scratching the surface and creating a sharper edge.”

Tony suggests a less costly, more efficient alternative to the wide-belt grinding machine: The Loewer Discmaster, which doesn’t rely on wide abrasive belts at all. By eliminating the belt, and using discs instead, Loewer eliminated a major source of energy loss by reducing heat generated through plastic deformation. The end result from Loewer is a machine that only requires about 35 amps at peak draw. Compare this to a conventional wide belt at 100A+. The cost savings is significant.

Tony suggests a less costly, more efficient alternative to the wide-belt grinding machine: The Loewer Discmaster, which doesn’t rely on wide abrasive belts at all. By eliminating the belt, and using discs instead, Loewer eliminated a major source of energy loss by reducing heat generated through plastic deformation. The end result from Loewer is a machine that only requires about 35 amps at peak draw. Compare this to a conventional wide belt at 100A+. The cost savings is significant.

Click here to read the rest of Tony’s interview and to get more insights into the Discmaster versus a wide belt machine. You can also visit the video section of our website to learn more about how these machines work.