We often get asked about tube finishing here. Tube is one of the materials that seems to be in every shop but no one notices. Some tasks with tube can be super simple and others can be a real pain in the butt. So to keep it short lets look at working with basic straight lengths and some bends.

Need an easy way to finish round tube?

With so many facilities working with round tube, it seems that giving a little information on how to finish round tube would be helpful. There are all manner of ways people have come up with but there are safe and easy processes you may not know about. I am not going to go over every possible way but rather focus on the safe and simple.

Finishing and sanding tube or pipe

Do you need to finish tube?

One of the more common tasks I am asked about day to day is dealing with round tube. There is so much of it used in all manner of products its seems near every one has to deal with it in some way or to some extent. It can be a simple process or as complex as putting together that build it yourself furniture we all love.

Finishing tubes can be easy.

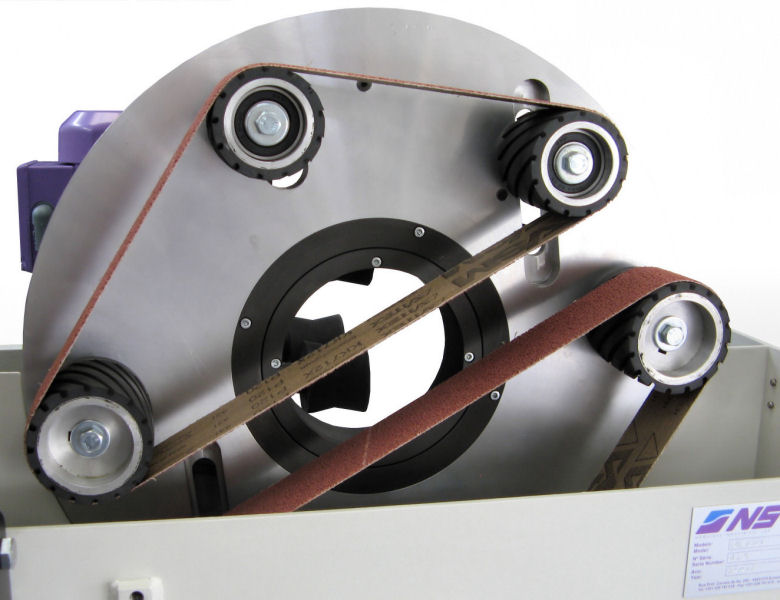

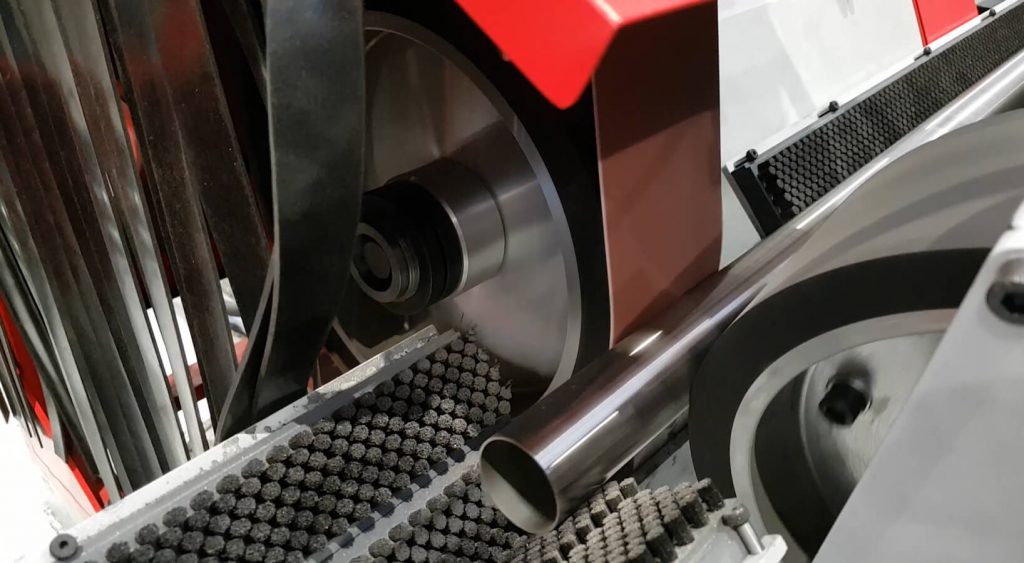

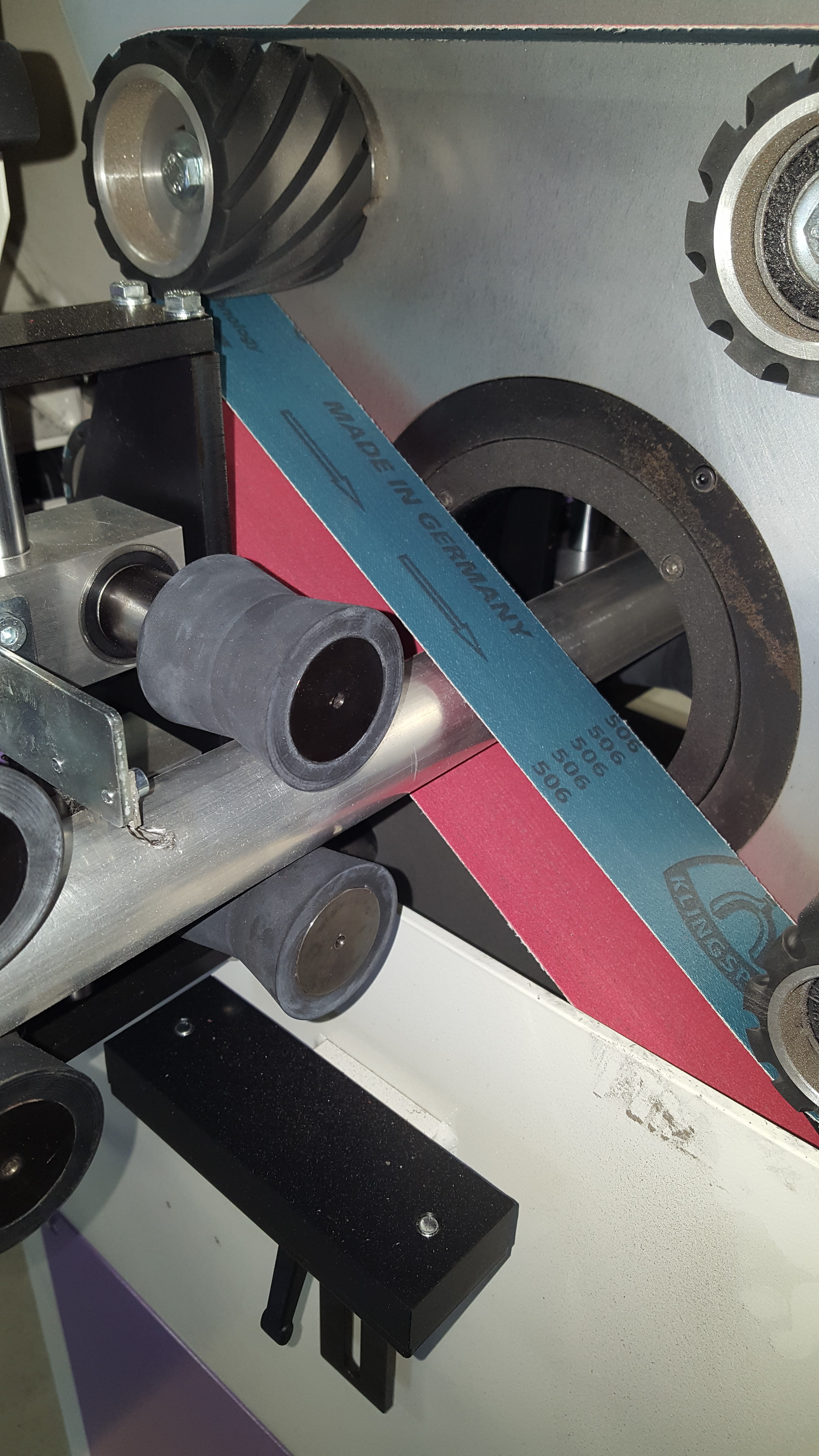

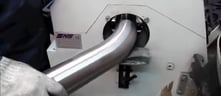

One of the tasks that tends to be problematic is the OD finishing of tube material. From hand finishing to placing tubes in a lathe there are all manner of ways people try to work with tubes. In reality there is a much more simple and fast way to do it that it seems many are not aware of. There is the centerless style of machine most have seen where the tube spins while being processed. Many are not fans of these due to the risks of the spinning tube. If there is a bend to the material the tube can flail around and get out of control. They also tend to be aggressive in a general sense as far as material removal. If you have nasty rust covered material with severe pits they would be the best option.

Choosing a Centerless or Planetary Grinding System for Tube Finishing

This is the fourth and final series of blog posts on tube finishing. Click on these links to read parts one, two and three.

When comparing centerless and planetary grinding systems, remember this fundamental difference: With a centerless system, the machine does the work of carrying the part through.

Once the part contacts the grinding and regulating heads, the part begins to spin rapidly and move forward. For the operator, it’s hands-off.

On a planetary system, once the tube is in the work area, the belts are grinding away, but the tube does not move. It is up to the machine operator to move the part through the grinding area, unless it is equipped with an automatic feeding device.

On a planetary system, once the tube is in the work area, the belts are grinding away, but the tube does not move. It is up to the machine operator to move the part through the grinding area, unless it is equipped with an automatic feeding device.

Both centerless and planetary systems offer varying degrees of automation. For the centerless machine, feeding is already a hands-off operation, so automation focuses instead on part loading and unloading.